Not only PCB assembly

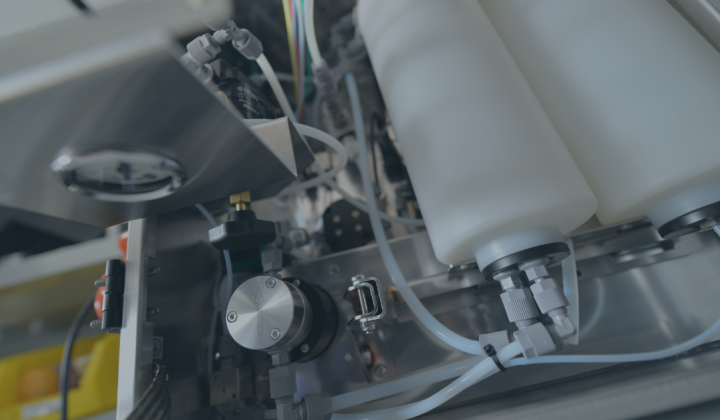

The services of contract electronics manufacturers are not limited to mere PCB assembly. At Assel, we are offering our clients a possibility of final assembly and electro-mechanical assembly on a turnkey basis - including material procurement, prototyping, testing, packaging and optimisation support.

During over 40 years of our presence on the market, we have gained extended experience not only in electronics assembly, but also in electro-mechanical integration Assel has all the necessary modern facilities and equipment for providing final assembly and testing, while our wide range of supplier base gives us access to high-quality material sources, ranging from mechanical parts, plastics, cable harnesses etc. Furthermore, we support our clients in sourcing, custom packaging and organizing out-bound logistics to your final Customers.

We support services from box build assembly level, to more advanced electro-mechanical system integration and cabinet assembly. Our certification and best practice quality standards ensure we can create devices of various application for industrial, medical and other sectors.

Our solutions for electro-mechanical assembly services

We are eager to help you with manufacturing challenging electro-mechanical assemblies, including a high-mix low-volume setup. With the use of a sophisticated ERP system with MRP2 loop, we can manage your project in different planning configurations, including Configure to Order and Build to Order basis.

We can manage the complete supply chain management, including the sourcing of materials based on your specification, including the procurement of custom-made parts.

Based on your requirements and testing procedure, we are able to conduct all of the necessary test processes.

Working with Assel, you can also count on assistance when it comes to production optimisation (Design for Manufacturability).

Our solutions for electro-mechanical assembly services

We are eager to help you with manufacturing challenging electro-mechanical assemblies, including a high-mix low-volume setup. With the use of a sophisticated ERP system with MRP2 loop, we can manage your project in different planning configurations, including Configure to Order and Build to Order basis.

We can manage the complete supply chain management, including the sourcing of materials based on your specification, including the procurement of custom-made parts.

Based on your requirements and testing procedure, we are able to conduct all of the necessary test processes.

Working with Assel, you can also count on assistance when it comes to production optimisation (Design for Manufacturability).

- quality control for incoming materials in compliance with AQL standards or Customer specific requirements

- complete production process according to your specification

- efficient supply chain management integrated within the Microsoft Dynamics AX ERP system, and the Manufacturing Execution System (MES) for optimised material management and traceability capability.

- efficient product management process including configuration and revision management, as well as component management (alternative management)

- reverse engineering services with 3D CAD

Our capabilities

Quality management

Assel can help you with electro-mechanical assembly as well as PCB assembly services. At Assel, we are offering PCB assembly according to the requirements of Class 2 and Class 3 of the IPC standard. We have our onsite IPC trainer who provides our employees with necessary education for meeting the IPC standard.

Furthermore, Assel has crucial certifications including ISO 9001 for quality management, ISO 22301 for business continuity management, ISO 14001 for environmental management and ISO 13485 for medical devices assembly.

Flexible approach

Assel is known not only for the quality of its services, but also for the flexibility. Complex designs may require changes on the go including the modifications of the product itself or the materials used for its manufacturing.

Assel does its best to make it possible for its clients to modify their projects on the go and also supports high-mix high-complexity production of electro-mechanical integration projects

Effective supply management

One of the key benefits of cooperating with Assel is the possibility of leveraging our supply chain management.

Since, we have been active in the industry of electronics manufacturing and electro-mechanical integration for almost half a century, we have established sophisticated and advance planning capabilities and built co-operation with local and global material suppliers. You can benefit from our knowledge resulting in organized planning processes, local sourcing capabilities and thorough inspection procedures for compliance with your requirements as well as our suggestions for optimisation.

The industries we support

For over 40 years, we have successfully assisted our customers with the complete process, providing complete assembly prototyping, series production, assembly, and testing services for complex or straightforward electro-mechanical systems.

We have experience in providing electro-mechanical assemblies for the industrial sector. Our key markets are: transportation, medical, lighting, security & safety, farming.