With more than 40 years of experience in electronics assembly, backed up by a team of a multifunctional, trained team of experts, we developed and continuously expand our manufacturing capabilities. Being a high mix low volume contract manufacturer specializing in integration of complex products and building sophisticated supply chains for such projects, we have developed a set of unique, practical solutions that allow us to effectively help our Customers to meet their goals.

At Assel, quality continuously remains our fundamental principle and first priority. This is confirmed by our Customers, as 82% of them perceive quality as our top core value.

We continuously invest in new technologies, as well as the development of integrated software solutions allowing a precise visibility of all production processes, including material management and order fulfilment. Material security, accurate delivery schedule, and high standard of workmanship maintain core elements of our production system.

After all, our vision is to become the preferred partner of choice for you.

Quality is our first concern

QUALITY ASSURANCE

Assel's Quality System is the outcome of over 40 years of experience in electronics assembly, followed by creating and refinement of best practices, tools and business processes. Our Customers state that quality standards and attention to detail have always been strongly valued at Assel.

We are actively involved through all stages of your product’s life cycle. The ultimate goal is to deliver manufacturing quality at the level reaching single PPM levels. Quality controls encompass all our contract manufacturing operations - from supplier selection and validation to incoming inspection of the materials to in-process control and out of box audits based on AQL standards. With the support of intelligent MES (Manufacturing Execution System) system, we have the ability to track the products in real time and react immediately to any occurrences.

Aside from investments in advanced software solutions and world-class manufacturing equipment that embraces a wide range of inspection and testing capabilities we work in line with effective quality tools and standards. Using a competence matrix, we select appropriately trained operators with suitable skills for the processes required within your project.

Quality has always been the fundament of our contract electronics manufacturing services operations and throughout the years we have created a culture of continuous improvement, where high performance is matched with world class quality systems and rigorous technical solutions that allow for providing PCBA assembly, box build and systems integration and electro-mechanical integration services - in line with the requirements of your market segments. It is in our DNA.

This is precisely the reason why our Customers trust us. We do what we say and we deliver results. Based on the recent 2019 survey, 100% of our Customers claimed they are satisfied with our services.

Quality is our first concern

QUALITY ASSURANCE

Assel's Quality System is the outcome of over 40 years of experience in electronics assembly, followed by creating and refinement of best practices, tools and business processes. Our Customers state that quality standards and attention to detail have always been strongly valued at Assel.

We are actively involved through all stages of your product’s life cycle. The ultimate goal is to deliver manufacturing quality at the level reaching single PPM levels. Quality controls encompass all our contract manufacturing operations - from supplier selection and validation to incoming inspection of the materials to in-process control and out of box audits based on AQL standards. With the support of intelligent MES (Manufacturing Execution System) system, we have the ability to track the products in real time and react immediately to any occurrences.

Aside from investments in advanced software solutions and world-class manufacturing equipment that embraces a wide range of inspection and testing capabilities we work in line with effective quality tools and standards. Using a competence matrix, we select appropriately trained operators with suitable skills for the processes required within your project.

Quality has always been the fundament of our contract electronics manufacturing services operations and throughout the years we have created a culture of continuous improvement, where high performance is matched with world class quality systems and rigorous technical solutions that allow for providing PCBA assembly, box build and systems integration and electro-mechanical integration services - in line with the requirements of your market segments. It is in our DNA.

This is precisely the reason why our Customers trust us. We do what we say and we deliver results. Based on the recent 2019 survey, 100% of our Customers claimed they are satisfied with our services.

Standards

PCBA: IPC-A-610 Class 2&3

Cable Harnesses: IPC-A-620

Bare PCB: IPC-A-600

Rework: IPC 7711/7721

MSL: IPC/JEDEC-J-STD-020/033

Quality Tools

PFMEA

PPAP

Control Plans

8D Methodology

5S

CTQ

TPM

Value Stream Mapping

Poka-Yoke

Daily Management Boards

Workmanship

Assel complies with IPC standard Class 2 & Class 3 requirements - key manufacturing standards for the electronic assembly services industry.

All our employees are continuously trained according to IPC training programs. We have access to an IPC trainer onsite.

Electronics Assembly

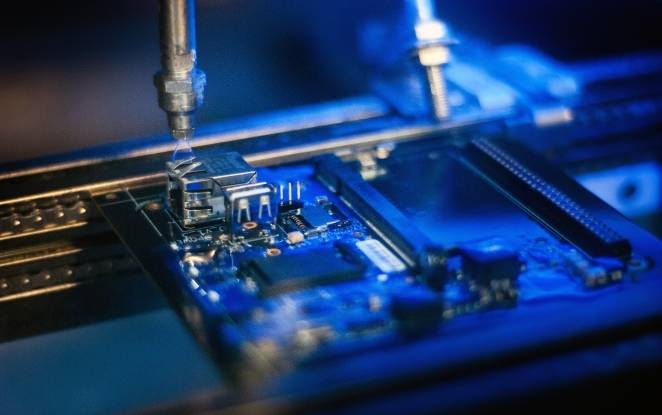

FROM SMT TO THT - PCBA ASSEMBLY AT IT'S BEST.

With the technology and supportive processes of a global contract manufacturer, while a tailored, flexible approach of a family-owned business, we help you to provide your products to the market faster, and of better quality.

Our experts operate within a high mix, high complexity production environment, on both batch and mass production scale. We possess state-of-art high-speed, as well as flexible, high-mix SMT lines electronics assembly line, that together with our internally developed management systems – allow for enhanced tracking of the production process.

Leverage our over 40 years of experience in electronics assembly across wide range of industries, in order to drive innovation, achieve higher quality and reach cost efficiencies.

Box-Build & System Integration

FROM BOX BUILD TO SYSTEMS INTEGRATION.

From industrial automation, control units and farming via more demanding and regulated markets, such as mining or maritime/offshore, we have been building and testing complex systems from single units to products that consist of hundreds of versions. Responsiveness, high quality, smart supply chain solutions and flexible order fulfilment is critical to meet your business objectives.

Together with you, we build sophisticated business models supported by advanced planning solutions, allowing to increasing your demand flexibility, shortening time-to market and increasing on-time delivery. From sourcing, to engineering support and optimization services, test to after-sales – we help you on each stage of the product life-cycle. We support you with engineering, product data management, sourcing and procurement, testing and after-sales services. Let our more than 40 years of experience in electronics manufacturing start working for you, today.

Conformal Coating & Potting

PROTECT YOUR PRODUCTS IN THE RIGHT WAY.

In order to offer more robust proudcts, an increasing amount of manufacturers seek contract electronics manufacturing providers with a range of competencies that includes conformal coating and potting applications. These are particularly valuable for devices functioning within severe environmental conditions that consider temperature, moisture, humidity, dirt or dust extremes, as well as shocks, vibrations or damage.

We offer our Customers automatic and repeatable conformal coating and potting applications, to ensure that your product performs in all kinds of environmental conditions.

Test & Inspection

ENSURING THAT YOUR PRODUCT WORKS.

We put enormous emphasis and pay particularly much attention on development of our test capabilities, available test technology and engineering skills. We have built a team of skilled and multidisciplinary engineers that ensure that the test systems we develop for our Customers, as well as the equipment that we manage and maintain are of first-rate performance.

Moreover, to maintain repeatable process and high quality of our production, we ensure that there is an optimum level of inspection controls within the process on each stage of the production. Depending on Customer requirements, we keep all control records and test data within our internal systems.