CONTRACT ELECTRONICS MANUFACTURING

Assel is a contract electronics manufacturing services provider with a primary focus on high mix, high complexity projects that require strong and proactive engineering contribution, sophisticated supply chain modelling and extensive technical capabilities in the area of electronic assembly services and electro-mechanical integration.

With over 45 years of experience in electronics manufacturing services, we understand that no two Customers are the same. Market segments, business models and products differ. Each Customer requires an individual approach, unique business model and supply chain strategy. We implement customised assembly standards as well as dedicated service that is focused on problem-solving and delivering results that meet your real business objectives.

HOW WILL YOU BENEFIT FROM WORKING WITH US?

Obtain Flexibility

Fast decision making is crucial in today’s world. As a private EMS, our decision making process is very swift. Such is coupled up with the ability to implement a robust supply chain model covering unknown demand and unpredictable incidents, simultaneously minimising excess material – it is a road to success.

Solve Problems

We focus on your problems, "pain points" and individual goals. Whether, it is a technical or supply chain related barrier, we identify adequate solutions and operational models focused on on the requirements of your market segment and the ability to fulfil your goals. All, in a more reliable and flexible manner.

Increase Quality

You cannot buy 40 years of experience in electronics assembly. With experience comes real-life practical solutions and reliability that is crucial for our Customer's success. We effectively follow your specification based on robust management systems, and that is why our Customers perceive quality of manufacturing as one of our biggest advantages.

Gain Trust

Trust is an essential value. One seeks a partner who fulfils his promises and does not fail to meet one’s objectives. We provide realistic, practical solutions, and work closely together with our Customers to meet the goals that are crucial for them. Our approach does work. Based on recent survey 100% of our Customers would recommend us to others.

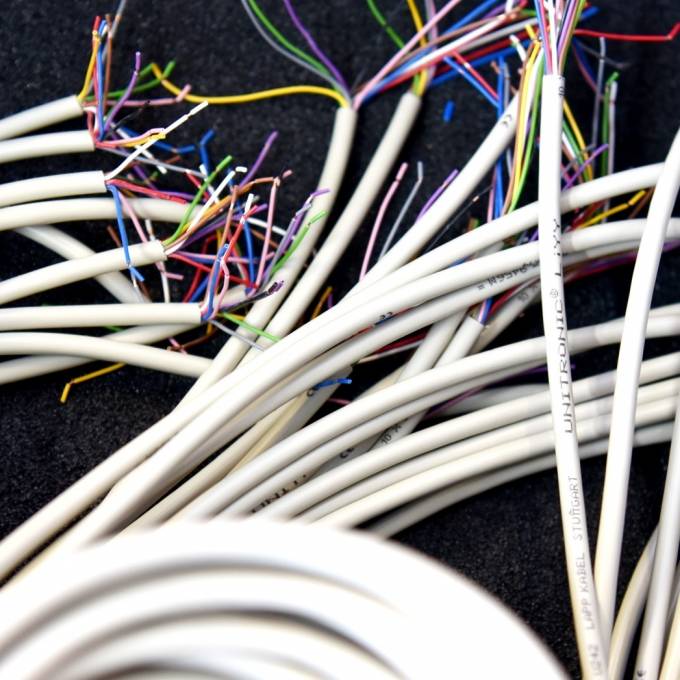

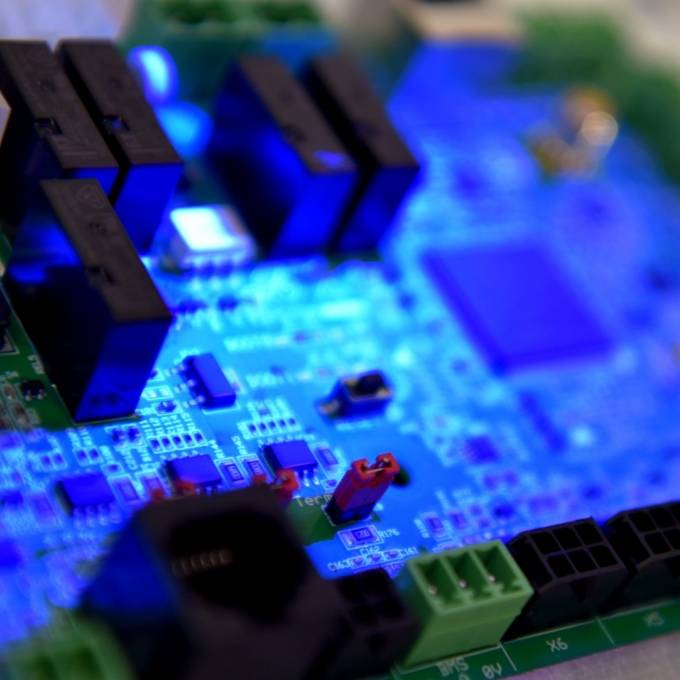

High-complexity

We specialise in high mix, high complexity electronics assembly and electro-mechanical systems integration for demanding industries. With more than 40 years of experience in manufacturing, thousands of NPI's and millions of units assembled, we seek to support our Customers in achieving their most challenging goals when outsourcing their manufacturing operations.

Certified Partner

Third-party certification is always an objective and fair reference of one's capabilities. We operate in line with IPC-A-610 (class 2&3) and possess four ISO approved management systems:

- Quality (ISO9001)

- Medical Devices (ISO13485)

- Environment (ISO14001)

- BCM (ISO22301)

ELECTRONIC MANUFACTURING SERVICES: KEY MARKETS

Industrial

We support you with access to variety of engineering services, state-of-art manufacturing technologies and supply chain competencies that will allow for optimization of your costs, repeatability and faster time-to-market.

MedTech

We provide ISO 13485 certification and have a team of experts with experience in electronics assembly for medical electronics manufacturing. They offer advanced inspection and control technology, systems and organization knowledge, and implement parts traceability throughout the manufacturing process to ensure the reliability and safety of their products.

Energy & Cleantech

Assel specializes in manufacturing highly efficient electronic systems for customers in the energy and cleantech sectors, providing a complete range of services from PCBA to systems integration.

Transportation

Assel supports Automotive, Rail and Public Sectors market. Our Customers receive a firm service focused on their business objectives and practical needs. We improve competitenvess by attention to detail, reliability and consistent quality.

Connectivity

In Assel, in line with our overall approach, we focus on delivering connectivity electronics for demanding professional and industrial applications, building on our long-term relationships with customers and deep application knowledge in the target industries

YOUR RESULTS ARE WHAT MATTER! LET'S GET STARTED.

NEWS & EVENTS

Assel Scales Up Its Sustainability Operations

+ Learn more

24.07.25

Development of Conformal Coating competencies in Assel

+ Learn more

10.10.23

Assel invests in a new X-RAY machine

+ Learn more

10.02.23

Alihankinta

Tampere, Finland

TESC

30.09.25 - 02.10.25

+ Learn more

22.07.2025

Subcon

Birmingham, UK

The NEC

04.06.25 - 05.06.25

+ Learn more

08.04.2025

Southern

Farnborough, UK

Farnborough International

04.02.25 - 06.02.25

+ Learn more

20.12.2024