What is a PCB Assembly?

Our PCB Assembly services incorporate both SMT (Surface Mount Technology) and THT (Through-Hole Technology) and are supported by ruggedization services, such as conformal coating and potting, together with extensive test & inspection capabilities.

We support our Customers in both:

- High-mix Low-volume (HMLV) PCB Assembly series - typically tens to hundreds product versions and/or configurations and production batches from 1 unit to thousand pieces.

- Low-volume High-mix (LMHV) PCB Assembly series – batches ranging from thousands to tens of thousands pieces.

Our core strengths come from the ability to manage high-complexity projects, due to a strong focus on quality management and operational excellence. Our Customers benefit from PCB Assembly Europe with wide organizational skills, engineering and test competences, as well as advanced supply chain management & planning solutions.

PCB Manufacture and Assembly is in line with IPC Class 2 & Class 3, with an certified IPC trainer in-house, as well as offer bothlead-free (RoHS) and leaded manufacturing capabilities.

PCB Assembly Europe

More and more companies are moving their production to Europe. Poland clearly stands out among European countries due to its ability to offer relatively low labor and production costs by offering a highly qualified workforce and a modern work culture. All this helps to meet the high demands of OEM manufacturers. Assel's Smart Factory is based in Central Europe in Poland. We are located near Gdańsk only 20 minute's drive from the airport.

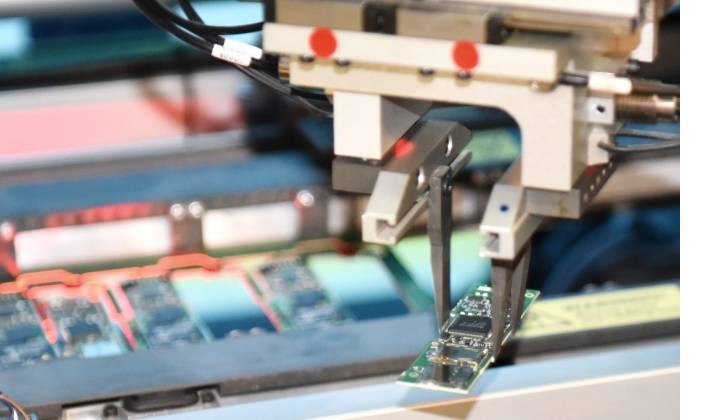

SMT Assembly / THT

PCB Assembly Europe with the technology and supportive processes of a global contract manufacturer, yet the flexibility level of a small private business - we support you with the newest and wide range of technological expertise.

SMT Assembly:

- Three high-speed/flexible SMT lines: 550,000 cph (Yom: 2016 or higher)

- Sophisticated SMT line with 3D SPI and multiple 3D AOI’s systems

- Technology: PoP, pin-in-paste, fine-pitch BGA, 0201 components

- MSD control & history management / ESD Management

- Temperature & humidity control

- Automated labeling

- X-Ray inspection

THT:

- Automated Through-Hole Assembly (Radial),

- Wave soldering (Nitrogen) automated Radial Assembly

- Manual soldering cells & lines

Leverage our nearly 40 years of experience in electronic assembly services/PCBA service across wide range of industries, in order to drive innovation, achieve higher quality and reach cost efficiencies.

SMT Assembly / THT

PCB Assembly Europe with the technology and supportive processes of a global contract manufacturer, yet the flexibility level of a small private business - we support you with the newest and wide range of technological expertise.

SMT Assembly:

- Three high-speed/flexible SMT lines: 550,000 cph (Yom: 2016 or higher)

- Sophisticated SMT line with 3D SPI and multiple 3D AOI’s systems

- Technology: PoP, pin-in-paste, fine-pitch BGA, 0201 components

- MSD control & history management / ESD Management

- Temperature & humidity control

- Automated labeling

- X-Ray inspection

THT:

- Automated Through-Hole Assembly (Radial),

- Wave soldering (Nitrogen) automated Radial Assembly

- Manual soldering cells & lines

Leverage our nearly 40 years of experience in electronic assembly services/PCBA service across wide range of industries, in order to drive innovation, achieve higher quality and reach cost efficiencies.

PCB Assembly process competences:

Traceability

Assel utilizes an in-house developed MES (Manufacturing Execution System) system, that supports:

- Traceability

- Directly integrated with the ERP system & production equipment, allowing for online data interchange

- Paperless documentation & revision management

- Real-time production execution visibility

Workmanship

Assel complies with IPC standard Class 2 & Class 3 requirements - key manufacturing standards for the electronic assembly services industry.

All our employees are continuously trained according to IPC training programs. We have access to an IPC trainer onsite.

Lead-time Management

Our modified daily run MRP2 loop and planning competences, allow us to minimize electronics assembly material lead-times, cover unexpected additional orders from your Customers, as well as minimise the risks of delays.

Prototyping

We deliver in PCBA service prototype builds for our Customers. This is accompanied with product evaluation services (eg. DfM, component engineering), as well as procurement services.

Conformal Coating

Working in harsh environments require adequate protection. We support our Customers with:

- Selective Conformal Coating (spray width control)

- Potting (electronically controlled dozes of epoxy / polyurethane).

Test & Inspection

Our printed circuit board assembly service include inspection & test capabilities:

- Inspection: inline 3D AOI & 3D SPI, X-Ray

- Test: Functional, In-circuit (ICT), Safety (Burn-in, Hi-Pot) and Environmental (Climate Control / Shock)

Technology

Core Capabilities & Technology

At Assel, we possess the following core technical capabilities. We continously expand our competencies, in order to support our Customers with higher quality level of printed circuit board assembly (PCBA), box build, systems integration and supporting services.

- Standards: Production in accordance with international standards, IPC Class 2 & 3

- SMT: software controlled, high-speed SMT Assembly lines (01005) inc. PoP, pin-in-paste, fine-pitch BGA

- THT: automated Through-Hole Assembly - Wave Soldering (Nitrogen) & Manual Soldering

- Coating: automated Conformal Coating & Potting technologies

- Test: FCT test development and variety of testing methods, incl. ICT, Safety, Environmental

- Inspection: Inline 3D AOI, inline 3D SPI inspection, 3D X-Ray

- Quality Control: Incoming inspection & in-process measurements

-

Pick & Place

Pick & Place Technical Capabilities

- High-speed, software controlled pick&place machines

- YoM: 2016 or higher

Pick & Place:

- From 01005 compnent size

- From 12 Pitch

- BGA and Mini BGA

- Pin In Paste

- PoP – package on package

- Stack (MA) Matrix Tray

- Paste & Glue

Reflow:

- 2 Sided SMT Reflow

- Nitrogen SMD Reflow

- High temperature

- Pb and Pb free

-

Soldering

Soldering Technical Capabilities

Screen Printing:

- Step Stencil (Cross Over)

- Pb and Pb free

Soldering:

- No Clean Process

- Lead Free Hi Temperature

- Nitrogen Wave

- Spray Flux Application

- Nitrogen Reflow

- Soldering Point

- Manual Soldering

- Pb and Pb free

-

Inspection & Test

Inspection & Test Capabilities

Inspection:

- 2D & 3D Inline Automated Optical Inspection (AOI)

- 3D Automated X-Ray (AXI)

- 3D Automated Solder Paste

- Cross Section

- Coordinate Measuring Machine

- Manual Visual Inspection

Test:

- Functional Test

- In-circuit test (ICT)

- Enviornmental tests (Thermal Shock Chamber)

- Burn-In Test

- High VoltageTest

- Stress Test

- Strain tests

- Leakage tests

-

Conformal Coating & Potting

Conformal Coating & Potting

- Assembly Cleaning

- Conformal Coating:

- ASYMTEK Select Coat® SL-940 Series conformal coating system for inline production

- Film coater SC-104 with rotate options

- Precision head available

- Laser Fan Width Control

- UV system control

- Curing

- Potting:

- 2 applications valid for two different compounds

- Repeatable process: electronically controlled dozing

- Different types of materials (Epoxy, Polyurethane, Silicones)

- Underfill

- Assembly Cleaning

-

General Technology

General Capabilities

- Software:

- Manufacturing Execution System (MES) - incl. traceability

- Production Planning integrated with MES and ERP

- Documentation Management: M-Files

- ERP: Microsoft Dynamics AX

- EDI & API information exchange

- Marking: automatic Label & Laser marking systems

- Depanelling: Router / V-cut / Punch

- Production Equipment: Assembly lines & assembly cells design & build

- Milling & Drilling: Working area 740 x 740 x 150 mm

- Problem Solving: Failure Analysis & Troubleshooting

- BGA/LG Rework (balling & reballing)

- Programming: serial Flash programming

- Software:

Technology

-

Pick & Place

Pick & Place Technical Capabilities

- High-speed, software controlled pick&place machines

- YoM: 2016 or higher

Pick & Place:

- From 01005 compnent size

- From 12 Pitch

- BGA and Mini BGA

- Pin In Paste

- PoP – package on package

- Stack (MA) Matrix Tray

- Paste & Glue

Reflow:

- 2 Sided SMT Reflow

- Nitrogen SMD Reflow

- High temperature

- Pb and Pb free

-

Soldering

Soldering Technical Capabilities

Screen Printing:

- Step Stencil (Cross Over)

- Pb and Pb free

Soldering:

- No Clean Process

- Lead Free Hi Temperature

- Nitrogen Wave

- Spray Flux Application

- Nitrogen Reflow

- Soldering Point

- Manual Soldering

- Pb and Pb free

-

Inspection & Test

Inspection & Test Capabilities

Inspection:

- 2D & 3D Inline Automated Optical Inspection (AOI)

- 3D Automated X-Ray (AXI)

- 3D Automated Solder Paste

- Cross Section

- Coordinate Measuring Machine

- Manual Visual Inspection

Test:

- Functional Test

- In-circuit test (ICT)

- Enviornmental tests (Thermal Shock Chamber)

- Burn-In Test

- High VoltageTest

- Stress Test

- Strain tests

- Leakage tests

-

Conformal Coating & Potting

Conformal Coating & Potting

- Assembly Cleaning

- Conformal Coating:

- ASYMTEK Select Coat® SL-940 Series conformal coating system for inline production

- Film coater SC-104 with rotate options

- Precision head available

- Laser Fan Width Control

- UV system control

- Curing

- Potting:

- 2 applications valid for two different compounds

- Repeatable process: electronically controlled dozing

- Different types of materials (Epoxy, Polyurethane, Silicones)

- Underfill

- Assembly Cleaning

-

General Technology

General Capabilities

- Software:

- Manufacturing Execution System (MES) - incl. traceability

- Production Planning integrated with MES and ERP

- Documentation Management: M-Files

- ERP: Microsoft Dynamics AX

- EDI & API information exchange

- Marking: automatic Label & Laser marking systems

- Depanelling: Router / V-cut / Punch

- Production Equipment: Assembly lines & assembly cells design & build

- Milling & Drilling: Working area 740 x 740 x 150 mm

- Problem Solving: Failure Analysis & Troubleshooting

- BGA/LG Rework (balling & reballing)

- Programming: serial Flash programming

- Software:

-

Technology

Core Capabilities & Technology

At Assel, we possess the following core technical capabilities. We continously expand our competencies, in order to support our Customers with higher quality level of printed circuit board assembly (PCBA), box build, systems integration and supporting services.

- Standards: Production in accordance with international standards, IPC Class 2 & 3

- SMT: software controlled, high-speed SMT Assembly lines (01005) inc. PoP, pin-in-paste, fine-pitch BGA

- THT: automated Through-Hole Assembly - Wave Soldering (Nitrogen) & Manual Soldering

- Coating: automated Conformal Coating & Potting technologies

- Test: FCT test development and variety of testing methods, incl. ICT, Safety, Environmental

- Inspection: Inline 3D AOI, inline 3D SPI inspection, 3D X-Ray

- Quality Control: Incoming inspection & in-process measurements

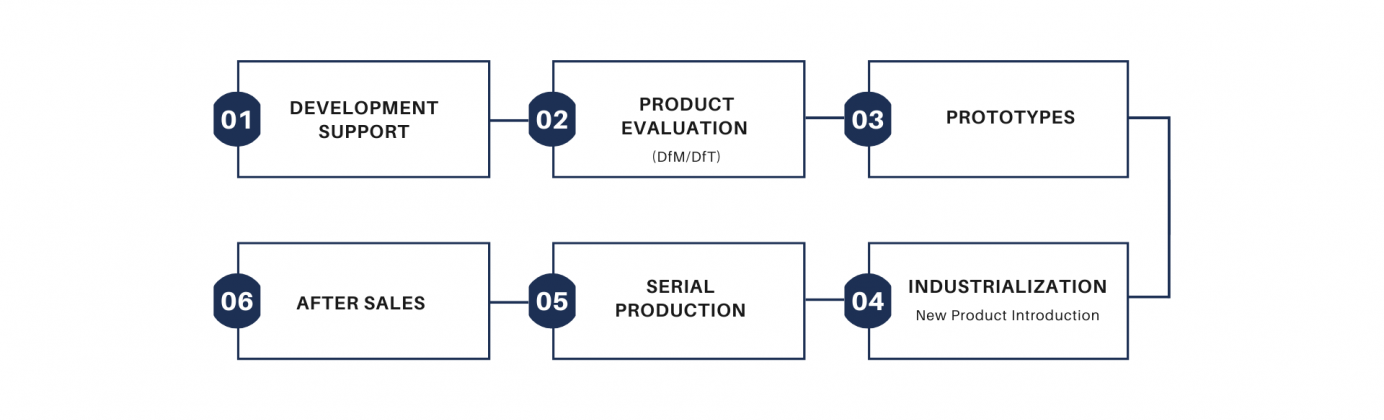

We support our Customers on each stage of the product life-cycle