The world of electronics relies on SMT surface mounting.

SMT (Surface Mount Technology) gradually replaces the THT (Through-Hole Technology) in electronics and this is in line with the aforementioned global trends. In order for the devices to be miniaturized, their components must also be of an appropriate size. Therefore, the components utilized in the production process must be very small. Of course, this must not affect quality, seeing as the technology market keeps setting the bar higher and higher.

SMT Surface Mount Technology definition

The SMT assembly of the electronic components is a guarantee of high quality used in the process of production of electronic devices. Surface Mount Technology (SMT) is a method of placing electronic components directly on the surface of a Printed Circuit Board (PCB). This technology, despite the need for an initial investment in machinery, allows for a reduction of system production costs (process automation), as well as more efficient use of the PCB space. Thanks to the introduction of this technology, it is possible to construct more complex and efficient electronic circuits, which translates into its growing popularity - visible for example in easy access to components. The advantage of such a technology is the possibility of embedding these components on both sides of the board.

SMT - the materials used

The installation of electronics with the use of this method requires materials dedicated for this solution:

- the Printed Circuit Board (PCB) - a board made of insulating material, covered with conductive foil, used for mounting electronic components,

- solder paste - a mixture of flux and small solder particles. For the sake of the SMT technological process, those with tin alloys are used,

- cleaner - with isopropyl alcohol, used for "wet" cleaning.

What does the SMT process of printed circuits look like?

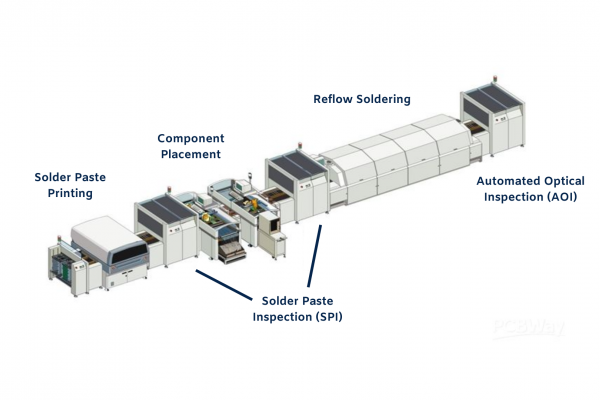

During the SMT process, the PCB goes through six stages:

1. Machine programming

Surface mounting starts with configuring all the machines involved in the process, according to the specifics required for the installation of the electronics for a given system. Machines such as the pick&place automaton or the AOI (Automated Optical Inspection) will require a plan to be created that is best generated from the CAD data that is often not available. For this reason, the design process utilizes the Gerber data, which are almost always available (they are required to manufacture a PCB). Therefore, if the Gerber data is the only data available, creating a list for the placement of centroids, components - the CPL file or the XY file can be time consuming, so the contracted electronics manufacturer can offer this type of service.

2. Application of the solder paste

The installation of the electronics starts with the application of the solder paste with the use of a template and a squeegee to the respective fields of a single PCB. This is the most common method of applying solder paste. The stage of application of the solder paste onto the board is encumbered with the highest risk of the occurrence of errors. To avoid errors, special attention should be paid to the shape and size of the apertures, the thickness of the template and the tensioning mechanism on the stencil machine frame.

3. Solder paste control

During the SMT process, an optical check is performed. The control systems used in solder paste stencil machines utilize the 2D technology, while dedicated SPI machines utilize the 3D technology. The SPI machine uses several cameras located in different places during the inspection process. This allows it to generate a three-dimensional image of the surface of the board. In the resulting image, the automatic inspection equipment compares the appearance of the individual paste application points. It tests the height, excess, deficiency, pollution, and bridges, among other things.

4. Stacking components

The subsequent part of the production process consists in placing the components on the applied solder paste. Each assembled element is retrieved from the package by means of a feeder, previously checked by the machine vision, and then precisely placed in the programmed location. This action is executed automatically by the pick&place machine. These automatons work at a remarkably high speed. Some of them are able to deploy up to 100 to 120 thousand components per hour.

5. Soldering in the brazing oven

The board with the components placed on it passes through a device which is an oven divided into several zones. It maintains different temperature values in each zone. The temperatures in them are selected depending on the details of the circuit structure. This is done in such a manner so as to ensure that the solder is distributed as efficiently as possible and high-quality soldering connections are created. Soldering connections are formed by the melting and subsequently solidifying solder paste.

6. The AOI inspection of the quality of the electronics installation

After the soldering process is completed, the finished board is usually inspected by the AOI (Automated Optical Inspection) equipment. Several high-resolution cameras scan printed circuit boards for the feature’s characteristic of the PCB surface. Stains, short-circuits, scratches, the use or absence of the wrong component, open circuits as well as disturbances in the solder area are detected. The resulting image is also compared with the image of the master plate loaded into the machine. This increases the effectiveness of pattern recognition algorithms.

Disadvantages and advantages of the SMT installation

Surface mounting bears a number of advantages:

- thanks to full automation, the installation of components is faster than manual placement of components on a PCB,

- components used in SMT installation can be smaller and lighter than their THT counterparts,

- this type of installation allows for a much higher component density (they are smaller) and provides a lot more connections per component (thanks to solder paste bonding),

- components can be placed on both sides of the PCB - the lack of reevings increases the area available for use,

- they are cheaper than its predecessors - automation of the production process.

There are not many drawbacks, but for the sake of having a comprehensive picture of the situation they should be mentioned:

- SMT requires a high level of attention to detail, greater than in the case of a THT installation,

- investment in the machine - the machine is expensive, but the investment pays for itself.

Good practices used in the SMT installation

Protection against electrostatic discharges

Electrostatic Discharge (ESD) is a threat to sensitive electronic devices. When installing sensitive components, earthed mats should be used to avoid damage to the components. A good EMS supplier will also have a resin-based flooring system that prevents electrification.

Protection of MSD components

Components of Moisture Sensitive Devices (MSD) are sensitive to moisture and are vacuum packed at the factory. After opening the package, the MSD component must be mounted and reflow soldering must be carried out within a strict time frame. After opening the package, one should check the tightness date on the label as well as the moisture indicator on the bag.

If the packaging of SMD components is not used during production, its contents should be stored in a drying cabinet. It is important to monitor the expiry and service life of the stored MSD components.

Double quality control

In addition to using the AOI machines for quality control of the finished product, it is worthwhile to execute an additional X-ray inspection of the unit. It picks up errors that are not discovered by the AOI - the number of voids in the soldering connections, or verification of the correct filling of the soldering hole in the soldering process.

The additional inspection reduces the risk of repeating errors in subsequent production processes.

Surface mounting, although initially a large investment, is currently one of the most effective ways of mounting electronics. It is an efficient, fast, precise, fully automated process. In order to increase production efficiency and minimize mistakes, it is worth considering finding contracted electronics manufacturers. Specialized companies are properly prepared specialists and production lines that meet the highest world quality and safety standards. The possibilities offered by the SMT significantly optimize production costs and thus increase the profitability of the company.

Read more about SMT assembly.