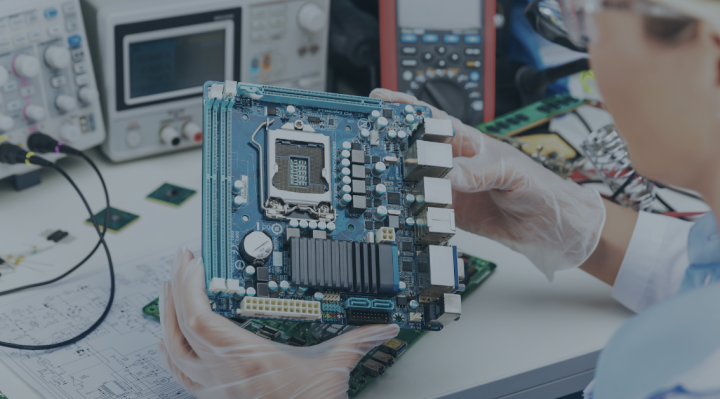

Contract electronics manufacturing, or electronic manufacturing services (EMS), is an alternative solution for companies that do not want to invest in their own production plant or do not have resources sufficient for starting and carrying out production at an appropriate level. EMS are provided by specialised companies, called contract EMS providers, which have not only the relevant technological facilities and trained staff, but above all the appropriate know-how and experience in electronics assembly.

Contract electronics manufacturing; what is it?

An EMS provider receives orders for performing electronic assembly services, which may involve the production of entire electronic devices or individual components. This process requires a number of skills from the EMS provider, such as: production process design, optimal production process management, assembly, testing, packaging and shipment of finished products, but also after-sales support, purchase of necessary materials by the EMS provider, supply chain management, redundant material management and cooperation with suppliers.

In terms of technology, various methods are used in electronics assembly, such as:

- THT (Through-Hole Technology) consisting in the electronics assembly by threading the leads of components through holes in a PCB or

- SMT (Surface-Mount Technology), i.e. electronics assembly of SMD (Surface-Mount Device) components on the surface of the PCB. SMD components used in the SMT are usually smaller and lighter than the parts used in the THT, so that they can be placed on smaller boards.

THT and SMT as well as SMD components are described in detail in the text titled What is the assembly of a PCB?

Benefits of working with an EMS provider

However, a provider of contract electronics manufacturing is not limited to the above activities. They also support the customer with experience by providing:

- Access to specialized resources and know-how: EMS providers have advanced technology and production experience, allowing them to deliver high-quality products on time, providing an OEM with access to knowledge and experience that can improve their products.

- Production flexibility: working with an EMS provider allows the OEM to quickly adjust production to variable demand. Even more so when the provider of contract electronics manufacturing services is able to carry out the production of low volume and high mix batches products that are often related, which is particularly beneficial for companies with varying production needs.

- Shorter production time: working with an EMS provider allows you to reduce the time necessary to produce the finished product.

- Cost savings: working with an EMS provider allows you to reduce production costs. All the more so that in the case of production volume exceeding the production capacity of the OEM, they would not only have to expand the machine facilities, but also hire and train additional employees.

However, savings also result from the ability to:

- eliminate possible design errors, especially since some EMS providers render DfM (Design for Manufacturability) services. They can help to increase efficiency, avoid potential problems in the production process and improve the quality and durability of the final product thanks to the optimisation of the design in terms of production technology and its costs.

- use cheaper and more accessible electronic components, which is particularly important in the current market situation of broken supply chains and major shortages on the market of electronic components,

- manage the material stocks, including surplus material,

- adjust the production rate to changes in market demand by accelerating or slowing down (to a certain extent) the production process.

Current market

To put it mildly, electronics assembly is not easy at the moment, as the market of electronic components has faced many challenges since the beginning of the COVID-19 pandemic. The restrictions on international transport introduced at that time led to a collapse supply chains and serious limitations in the production of electronic components. The situation is further complicated by the chip war - the trade conflict between the United States and China, which destabilises the market that has already been severely weakened.

All this causes increases in prices of many components and limitations in the availability of certain materials, as a result of which many electronics companies must face delays in production, and poses a major challenge for EMS providers and companies using their services.

However, an experienced provider of contract electronics manufacturing services usually has access to a much wider and global supply chain and works with proven suppliers, so it can offer much better component prices than the OEM could get. This is described in our text Security of the supply chain when working with a contract EMS provider for electronics assembly.

To conclude: services of an EMS provider can allow the OEM to avoid having to invest in their own production and to employ additional staff, instead focusing on its core business of designing and developing new products and customer service. However, the real benefits of working with an EMS provider lie in their experience and additional services they can offer to the OEM, as described in our text OEM outsourcing to contract manufacturers - what are the benefits?