The primary objective of the vast majority of manufacturers of original equipment (OEM) is growth, and this means new business areas and new customers. However, success understood in this way often has a different side, namely the inability to meet growing demand.

For this reason, manufacturers of original equipment quite quickly face a choice: they can either develop their own production, hire employees and engage in new technologies, or.... opt for outsourcing electronics manufacturing.

The second option is often more cost-effective and advantageous, as it not only allows for increased throughput, but frees the OEM from the obligation to assemble all the resources necessary for production. However, switching from in-house production to outsourcing electronics manufacturing is always a difficult decision and it is therefore worth looking at the advantages and possible disadvantages of doing so.

More time and resources for product development

Outsourcing electronics manufacturing allows contract manufacturers of original equipment to do what is most important to them, which is to focus on developing existing products and services, designing new ones, as well as marketing and sales. As the responsibility for production, quality and delivery falls on the contract EMS provider, contract manufacturers of original equipment can develop and launch new products ahead of the competition with peace of mind, track and analyse trends and deliver their products in ever shorter timeframes. And, above all, take care of capricious customers.

Expertise of the contract EMS provider

EMS service providers can take over the tasks of manufacturing, product inspection and testing and supply chain management from contract manufacturers of original equipment. They are also able to cope with changing requirements and quickly adapt production capacity to project specifications and respond flexibly to changes in the materials market and changes in demand for OEM products.

They also have the systems and management solutions to control quality at all stages of production, material flow, supply chain management, and a strong position in the materials market. Additionally, they are able to optimise production processes, build solutions to customer specifications, source alternative material sources, and offer the OEM a range of value-added services.

Value-added services

The systems, procedures and management solutions used – often built up over years based on organisational competence and good practice – allow EMS providers to offer many value-added services, such as:

Supply chain management

An OEM that chooses to self-manufacture has to set up the entire supply chain itself, take care of the quality and timeliness of deliveries, as well as control the delivered materials and store them properly. This is not only difficult, but is associated with considerable costs, as it requires the hiring of specialists and investment in ERP systems, as well as their correct configuration.

In contrast, an experienced EMS provider has a base of verified suppliers and a strong negotiating position already in place. At Assel, we carry out regular supplier audits and have based our claims process on NCR reports and 8D methodology.

Adapting manufacturing to fluctuating demand

Contract EMS providers are able to react quickly and flexibly to demand swaps at the OEM, which has a direct impact on overall costs. And by running the MRP (Material Resource Planning) system loop on a daily basis, Assel can not only make economically sound and appropriate purchasing decisions (accelerating and delaying deliveries, for example), but also manage production and excess material accordingly.

Responding quickly to changes in demand, in turn, allows an OEM, for example, to deliver a larger batch of products to the market and gain a competitive advantage.

Surplus material management

Assel uses an ERP system (Microsoft Dynamics AX) for proactive material planning integrated with an MES (Manufacturing Execution System) for tracking, managing and monitoring materials in the production process. This not only enables a rapid response to changing demand, but also minimises unused excess material, resulting in lower overall costs for contract manufacturers of original equipment.

Managing production and material during production

Adequate production management allows for the timely delivery of products ordered by the OEM and includes:

- planning of material requirements

- planning of necessary human resources

- control of individual production stages.

Optimised control of the production process enables:

- precise control of the production process

- efficient management of short-run production

- flexible reactions to changes in production and materials,

- high production quality

- reduction of OEM overheads due to minimisation of losses resulting from suboptimal material management in production

- ensuring conformity of materials delivered to the production line with the OEM's BOM, and

- reporting on the progress of subsequent production stages

In turn, management of material in production is made possible by identifying material labelled appropriately at the time of delivery.

Traceability

For some contract manufacturers of original equipment, it is extremely important to implement traceability procedures that allow them to meet regulatory requirements, but also to provide an efficient after-sales service. At Assel, we have two levels of traceability controls in place, which not only allow us to track each wafer through the production process, but also to record all installed components and their series.

Conducting inspections and tests

Current regulations and quality management systems oblige OEMs to carry out various types of inspections and tests on products arising during the production process. These include visual or manual inspections, inspections carried out by automated optical inspection systems, functional tests or in-circuit tests.

Contract EMS service providers are able to build test systems and design and execute tests according to the OEM's guidelines by taking over this responsibility from the OEM.

Support during product certification

Having certifications is currently necessary to market products, such as having the CE mark in the European Union. However, the need to meet certification requirements is linked to the introduction and maintenance of appropriate procedures, as defined in the regulations.

This is quite a complex process and EMS providers are able to effectively support OEMs during UL, TUV or ETL compliant audits and the preparation of the documentation necessary for certification.

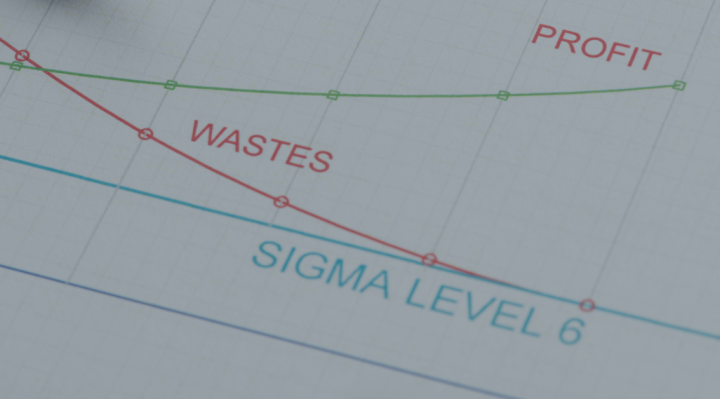

Lower costs

Although costs are rarely the main factor behind the decision to outsource, working with an EMS provider allows OEMs to avoid fixed costs such as investing in new equipment, production halls and maintaining and training staff, including highly skilled production engineers or managers. And also operational costs.

This is particularly important if the OEM's demand is volatile, making downtime costs during periods of reduced demand potentially catastrophic.

In addition, many EMS providers are able to reduce costs by implementing Lean-based manufacturing processes, or using economies of scale in material procurement. This is also possible by:

- Eliminating unnecessary inventory and reducing work in progress

- Reducing production lead times and therefore being able to fulfil more orders

- Efficient risk management

- Flexible management of production volumes and supply chains

Flexibility

The success of an OEM depends on getting products to market quickly and responding to increases or decreases in demand for products and services.

EMS providers are specialists in production execution. They are able to flexibly adapt to new and changing customer needs and ensure the supply of suitable components, as they have broad access to the purchasing market, which puts them in a better purchasing position.

Adapting production to changing demand is also possible due to the ability to delay or accelerate deliveries.

All of this means that EMS providers are not only able to deliver a quality service in a flexible manner, but also reduce the cost of production, making the OEM more competitive.

There are many reasons why OEMs opt for outsourcing electronics manufacturing. However, ultimately by choosing to outsource, the OEM becomes a partner in a mutually beneficial collaboration where both parties focus on their strengths.

For the OEM, the manufacturing process is simply how products are brought to market. Delegating this responsibility to an EMS provider, – who has the resources, tools, procedures and experience – allows the OEM to put all its energy into the design and development of its products and services. And this is why it is a win-win cooperation.

See how to build a relationship between EMS and OEM: https://asselems.com/en/4-tips-for-a-good-relationship-between-ems-and-oem