In the dynamic and competitive realm of Electronics Manufacturing Services (EMS), a distinguishing success factor is the quality and reliability offered by an EMS partner. To achieve this, an EMS partner adopts several strategic approaches: integrating automation in manufacturing processes, employing diverse control mechanisms during production, staying alert to potential risks, and perpetually seeking ways to enhance efficiency and output quality.

1. Harnessing the Power of Automation

Automation stands at the core of a modern EMS partner's strategy. By automating processes, an EMS partner ensures higher precision in assembling intricate components onto PCBs, a task that's becoming increasingly complex due to ongoing miniaturization. Machines' consistency and accuracy, compared to human labour's limitations, lead to fewer errors and enhanced product quality. Automation significantly boosts efficiency and contributes to cost-effectiveness, making the services of the EMS supplier more appealing in the competitive market.

2. Adapting Production Controls

A versatile EMS partner utilizes both fixed and programmable automation. Fixed automation, designed for specific tasks, assures uniformity and efficiency in repetitive processes. Programmable automation, such as robotic arms, provides flexibility, allowing the EMS partner to cater to various production requirements. This adaptability is vital in meeting OEM partners' diverse demands, ensuring consistent production quality and efficiency.

3. Proactive Approach and Continuous Improvement

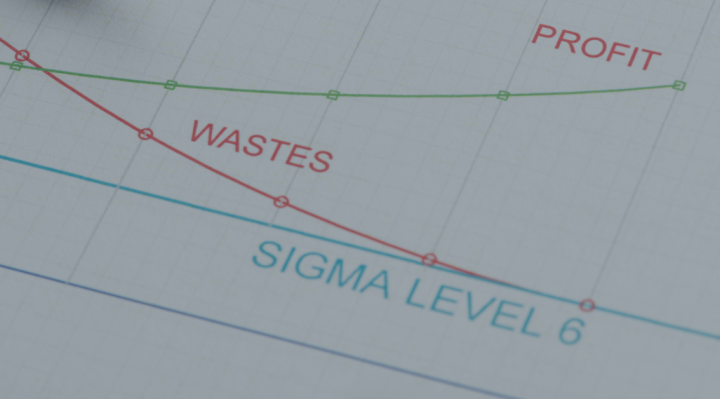

A proactive EMS partner is always vigilant about potential challenges, employing advanced automation aligned with the principles of Industry 4.0. Incorporating smart production strategies involves integrating systems with advanced sensors and technologies for real-time monitoring and precision control. This elevates product quality, enhances workplace safety, and reduces health risks, making the EMS partner's facility safer and more efficient.

4. EMS Partners and Industry Adaptation

An EMS supplier's role extends beyond just manufacturing; they must be attuned to the evolving demands of the market. By leveraging data and trend analysis, an EMS partner stays ahead of industry shifts, ensuring that they are equipped to adapt to new OEM requirements quickly. This agility is essential for maintaining a competitive edge and sustaining long-term partnerships.

In summary, the strengths of an effective EMS partner or supplier lie in their ability to integrate advanced automation, employ diverse production controls, and maintain a vigilant and adaptable approach to manufacturing challenges. Through these strategies, EMS partners not only guarantee superior quality and reliability in their services but also contribute to the broader success and innovation in the field of electronics manufacturing.