Lean Manufacturing, a transformative approach to production management, traces its roots back to the Toyota Production System (TPS) developed in post-war Japan. At its core, Lean is about maximising value while minimising waste - a philosophy that challenged traditional manufacturing paradigms and has since become a global benchmark for operational excellence, with particular relevance today for complex industries such as electronics manufacturing.

Originating from Toyota’s relentless pursuit of efficiency, Lean Manufacturing emphasises the elimination of activities that don’t add value from the customer’s perspective. This innovative system was not merely about cutting costs, but about fostering a culture of continuous improvement of operating performance (Kaizen) and respect for people. Toyota’s success popularised Lean principles worldwide, influencing industries far beyond automotive manufacturing.

The importance of Lean Manufacturing today is undeniable. Companies that embrace Lean achieve less waste, greater efficiency, smoother workflows, higher product quality, improved customer satisfaction, and stronger profitability and adaptability.

There are five principles of lean manufacturing, which serve as a roadmap for organisations seeking to enhance performance and deliver superior value. In the following sections, we’ll explore these principles in detail, providing insights into how they drive Lean Manufacturing success and how organisations across industries can apply them effectively.

1. Define Value: What Matters to Your Customer

In Lean Manufacturing, everything begins with understanding and defining value - but crucially, this value must be determined from the end customer's careful analysis, not from the company’s internal assumptions. Too often, organisations fall into the trap of believing they know what their customers want, only to later discover a costly mismatch between what they provide and what customers truly value.

Value, in Lean terms, is any activity or feature for which the customer is willing to pay because it meets their needs or solves their problems. It’s not about what the company thinks is important - it’s about aligning production and processes to deliver exactly what the customer desires.

For example, consider an OEM designing an industrial IoT device for commercial customers. The end users may prioritise device durability, long battery life, and reliable wireless performance over premium finishes or aesthetic details. If the OEM focuses on adding expensive design features rather than ensuring robust performance in harsh environments, they risk misaligning with customer needs and wasting resources on non-value-adding features - a mistake that can cascade through the EMS provider’s manufacturing process.

Validating Assumptions - Key to Productive Processes

Even seasoned managers can misinterpret what customers value most. That’s why it’s critical to validate your understanding of customer needs through robust tools such as:

These techniques help ensure that your organisation isn’t just guessing what matters, but is making informed, data-driven decisions to meet and exceed customer expectations.

By clearly defining value from the outset, businesses set the foundation for all subsequent Lean activities - from streamlining production processes to eliminating waste. This principle ensures that every resource invested contributes directly to manufacturing efficiency and, ultimately, business success.

2. Map the Value Stream: Visualising the Process

Once you’ve defined what truly matters to your customer, the next critical step in Lean Manufacturing is to map the value stream. This process visually captures every step involved in delivering a product or service. This approach enables organisations to see both value-added and non-value-added activities clearly, providing a roadmap for improvement.

At its core, Value Stream Mapping (VSM) helps companies answer essential questions:

- Where does value occur in our process?

- Where are the delays, redundancies, or inefficiencies?

- How can we eliminate waste to improve flow?

A value-added step is any activity that directly contributes to meeting customer requirements - for instance, assembling components to produce a functioning product. In contrast, non-value-added steps (or waste) include tasks like excess movement, waiting times, or redundant inspections that do not add value from the end customer’s reference point.

A Simple Value Stream Map

Here’s a simplified version of a typical value stream flow:

In this flow, organisations should analyse each part to determine whether it adds value or creates waste. Visual approaches like this help teams quickly identify bottlenecks and opportunities for improvement, empowering them to make data-driven decisions on the shop floor.

Case Study

Consider Company X, a mid-sized electronics manufacturer. Before mapping their value stream, their production process was bogged down by redundant quality checks and excessive inventory buffers. Through comprehensive VSM workshops, they identified several non-value-added steps, including unnecessary movement of materials between workstations and repeated inspections that added no incremental quality assurance.

By streamlining these steps and reorganising the shop floor for better flow, Company X reduced its average lead time by 30%, dramatically improving on-time delivery and customer satisfaction while reducing operational costs.

3. Create Flow: Eliminating Bottlenecks

After defining customer value and mapping the value stream, the third Lean principle focuses on creating flow, ensuring that work progresses smoothly and continuously through the production process without delays, interruptions, or bottlenecks.

A smooth workflow reduces waiting times, minimises inventory levels, and enhances responsiveness to customer demand. Yet in many organisations, fragmented layouts, inconsistent processes, and poor communication can all cause disruptions that reduce efficiency and increase costs.

Key Strategies to Improve Flow

To eliminate bottlenecks and promote seamless flow, organisations can adopt several proven strategies:

- Cellular Manufacturing: This involves organising workstations into small, self-contained cells that handle specific product families. Each cell is designed for optimal material and information flow, dramatically reducing transport times and handoffs.

- Standardised Work: By clearly defining the best-known method for every task, teams can minimise variation, improve predictability, and make it easier to train workers and balance workloads effectively.

- Balanced Workloads: Proper workload balancing across stations helps avoid underutilization in some areas while others experience bottlenecks.

Leveraging Digital Tools for Flow Improvement

In today’s environment, digital tools play a critical role in enabling continuous flow. Companies emphasise the importance of technology integration in Lean Manufacturing initiatives, offering platforms that:

- Provide real-time visibility into shop floor operations.

- Enable workers to identify and resolve bottlenecks quickly.

- Facilitate communication and collaboration among teams.

- Offer actionable analytics to drive improvement efforts.

For example, a digital dashboard could instantly highlight workstations where inventory is piling up or cycle times are lagging behind standards, allowing supervisors to intervene before minor issues become major delays.

By combining proven Lean manufacturing process with modern technology, organisations can create robust, flexible workflows that adapt quickly to changing customer needs and market conditions.

4. Establish Pull System: Demand-Driven Production

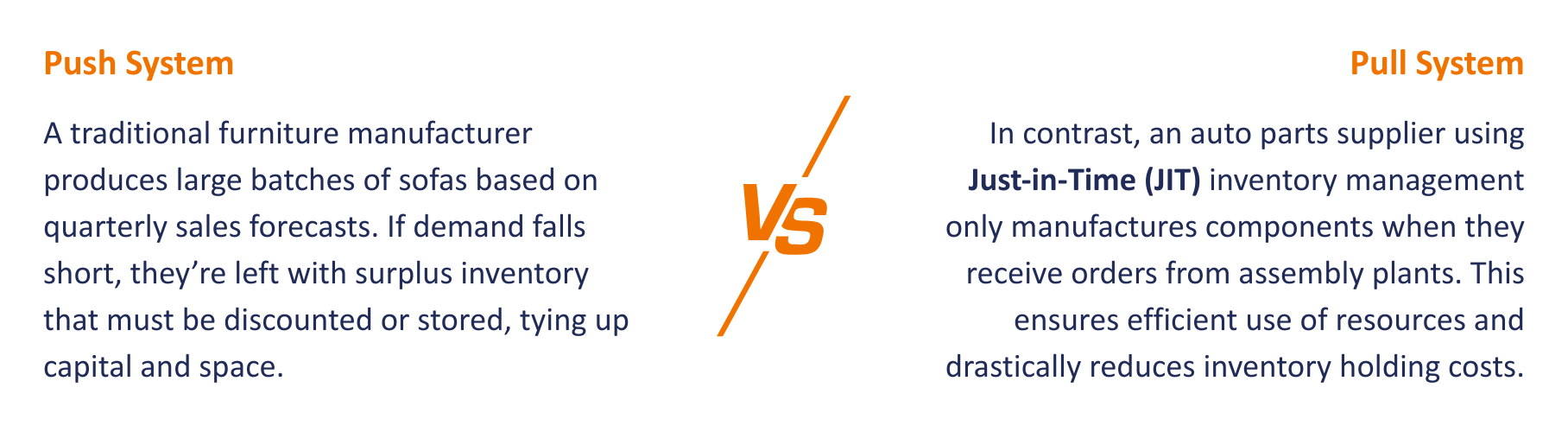

A central tenet of Lean Manufacturing is to “establish pull”, meaning that production is driven strictly by actual customer demand rather than forecasts or schedules. This is a critical shift away from traditional “push” systems, where goods are produced based on predicted needs and pushed through the supply chain, often leading to overproduction, excess inventory, and wasted resources.

In a “pull” system, work begins only when there is a downstream demand. This approach ensures that every product or service created is directly tied to an immediate customer requirement, minimising inventory levels, reducing lead times, and improving responsiveness.

Comparison - Push vs. Pull

The pull approach, when implemented properly, helps organisations remain lean, flexible, and customer-focused.

Common Pitfalls

However, transitioning to a pull system is not without risks. One of the most common mistakes is understocking critical components or raw materials, leading to stockouts, production delays, and frustrated customers. While Lean Manufacturing encourages lower inventory levels, it’s essential to maintain a careful balance to avoid operational disruptions.

Organisations can mitigate this risk by:

- Establishing strong supplier relationships.

- Improving demand forecasting accuracy.

- Using Kanban systems to visually control inventory levels and reorder points.

By thoughtfully establishing pull, companies can achieve the Lean Manufacturing goal of making what the customer wants, when they want it - and nothing more.

5. Pursue Perfection: Continuous Improvement (Kaizen)

The final principle of Lean Manufacturing is to pursue perfection, which reflects the philosophy of continuous improvement, or Kaizen. This principle reminds organisations that Lean is not a one-time project or a quick fix - it’s a mindset and a long-term cultural commitment to excellence.

Lean-thinking organisations understand that no process is ever truly perfect. There’s always room to improve quality, reduce waste, and enhance efficiency. By fostering a culture where every employee is empowered to identify and solve problems, companies can achieve sustained improvements and adaptability in a fast-changing market.

Lean Management as an Ongoing Journey

Rather than implementing Lean tools and walking away, organisations practising Kaizen embed continuous improvement into their daily operations. Small, incremental changes, when made consistently over time, add up to significant performance gains.

For example, encouraging workers on the factory floor to suggest improvements, no matter how minor, helps create a culture of ownership and innovation.

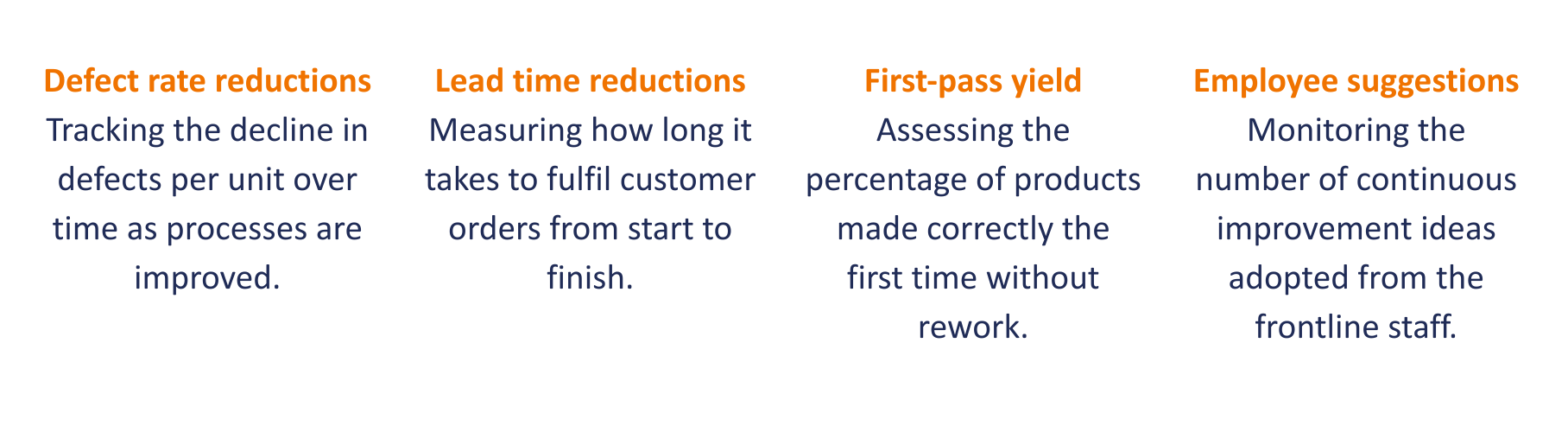

Key Metrics to Track Progress

To effectively pursue perfection, it’s essential to measure progress using clear and actionable metrics. Common Lean Manufacturing performance indicators include:

By rigorously tracking these metrics, organisations can see tangible evidence of improvement while maintaining momentum on their Lean Manufacturing journey.

In short, pursuing perfection means embedding continuous improvement into the DNA of the organisation, ensuring that processes evolve and adapt in pursuit of ever-greater value stream for customers.

Bonus: The 8 Wastes of Lean (Muda)

A core concept underpinning Lean Manufacturing is the relentless focus on eliminating waste, or “muda” - a Japanese term meaning any activity that consumes resources but creates no value for the customer. Recognising and addressing these wastes is essential to achieving Lean efficiency.

The original Toyota Production System (TPS) identified seven classic types of waste, with an eighth later added to reflect modern challenges. Together, these form a critical framework for identifying inefficiencies in any process.

The 8 Wastes of Lean Five Principles with Countermeasures

A Visual Framework for Waste Reduction

Using this comparison table makes it easy for teams to identify areas of inefficiency in their operations. By systematically reviewing operations through the lens of these eight wastes, organisations can uncover hidden inefficiencies and implement countermeasures to reduce costs, improve quality, and accelerate delivery times.

Remember: recognising muda is just the beginning - successful Lean organisations develop habits and processes that actively seek out and eliminate waste every day.

How to Implement the Five Lean Principles in 2024

Implementing Lean Manufacturing is no longer just about copying Toyota’s playbook - it’s about adapting Lean principles to today’s fast-paced, technology-driven environments. Organisations that succeed focus on practical, actionable steps to embed Lean thinking into daily operations. Here’s a step-by-step roadmap to guide implementation in 2024:

Step 1: Start with Pilot Projects

Launching pilot projects is a proven method for building momentum. By targeting a specific process or production line where quick wins are achievable, organisations can demonstrate tangible results early on. These wins help generate buy-in across teams and management, creating a foundation for broader Lean Manufacturing adoption.

Examples of good pilot areas include:

- A high-volume assembly line with frequent bottlenecks.

- A warehouse operation where inventory turnover is slow.

- A maintenance process that suffers from repeated delays.

Success stories from these pilots can showcase reduced lead times, lower defect rates, or improved throughput, encouraging further investment in Lean initiatives.

Step 2: Train Teams on Lean Manufacturing Basics

A critical factor in any successful Lean implementation is investing in team training. Frontline employees and managers alike must understand Lean thinking concepts, tools, and techniques to contribute effectively.

Educational resources that often integrate Lean with Six Sigma methodologies can provide teams with a solid foundation. Combining Lean Manufacturing with Six Sigma’s data-driven rigour ensures improvements are not just implemented but also sustained and measurable.

Key topics to include in training:

Step 3: Use Software for Real-Time Monitoring

In 2024, digital tools are essential to support and scale Lean practices. A variety of platforms offer real-time monitoring and analytics to visualise performance, identify bottlenecks instantly, and engage teams in improvement efforts.

Benefits of integrating software include:

- Real-time dashboards to track key performance indicators (KPIs).

- Alerts when processes deviate from standards or targets.

- Digital collaboration tools enable cross-functional problem-solving.

By combining these steps, companies can create a structured and modern Lean Manufacturing transformation strategy - one that delivers immediate improvements while laying the groundwork for continuous growth and innovation.

Common FAQs - What to know before implementing lean?

Lean Manufacturing is a widely discussed topic, but many people still have key questions about how it works and where it applies. Let’s address some of the most frequently asked questions to clear up common misconceptions:

Q: Is Lean only for manufacturing?

A: No - while Lean originated in manufacturing, its principles have proven highly effective across many industries. Sectors such as healthcare, information technology (IT), logistics, and even government services now use Lean methods to improve efficiency, reduce unnecessary processes, and ensure the remaining steps run smoothly.

For example:

- In healthcare, hospitals use Lean to reduce patient wait times and streamline care delivery.

- In IT, software development teams apply Lean principles to speed up workflows and improve product quality (e.g., Lean-Agile practices).

- In service industries, Lean helps optimise processes like call centre operations or back-office functions.

Lean’s core philosophy - focusing on value from the customer’s perspective and eliminating unnecessary movement - is universally applicable wherever processes exist.

Q: How does Lean differ from Six Sigma?

A: Lean and Six Sigma are often mentioned together, but they are distinct and complementary approaches.

- Lean focuses primarily on identifying and eliminating waste (muda) to improve flow and reduce cycle times.

- Six Sigma is aimed at reducing variation and defects through statistical analysis and rigorous problem-solving.

In practice, many organisations use a “Lean Six Sigma” hybrid approach, combining Lean’s emphasis on creating flow and efficiency with Six Sigma’s focus on precision and consistency. This integrated methodology helps organisations tackle both process speed and quality simultaneously, delivering stronger performance improvements.

Conclusion

Lean Manufacturing remains one of the most powerful frameworks for driving operational excellence, cutting waste, and delivering superior customer value. The five principles of lean manufacturing - Define Value, Map the Value Stream, Create Flow, Establish Pull, and Pursue Perfection - work together to form a practical and adaptable roadmap for continuous improvement across industries.

By implementing these five core principles, organisations can develop workflows that are not only more efficient but also more responsive to changing customer needs, competitive pressures, and technological advancements. This is particularly important in today’s dynamic landscape, where industries such as electronics manufacturing, healthcare, logistics, and IT face increasing demands for speed, smooth flow, quality, and flexibility.

The importance of Lean lies not just in the immediate improvements it delivers - such as reducing inventory, shortening lead times, and cutting costs - but also in the cultural transformation it encourages. Lean-thinking organisations cultivate a mindset where every employee, from shop floor operators to executives, is empowered to identify problems, suggest improvements, and contribute to overall business success. This cultural shift fosters accountability, engagement, and innovation, ensuring that improvements are sustained over the long term.

Moreover, Lean principles are uniquely suited to today’s data-driven, digital environments. With the widespread adoption of Industry 4.0 technologies, such as IoT sensors, real-time monitoring platforms, and advanced analytics, organisations can now gain unprecedented visibility into their processes. Principles of lean manufacturing complement this by providing the tools and mindset needed to act on this data, identify inefficiencies, and implement targeted improvements rapidly.

In industries such as electronics manufacturing, Lean’s impact is especially profound. By focusing on reducing waste in areas like component handling, line changeovers, testing, and rework, manufacturers can dramatically improve first-pass yields, reduce defect rates, and meet increasingly stringent customer expectations. The ability to respond quickly to fluctuating demand while maintaining high standards of quality is a critical differentiator, and Lean principles provide the framework to achieve this balance.

Lean is not a one-size-fits-all solution, but its core philosophy - focusing relentlessly on value from the customer’s perspective and eliminating anything that does not contribute to that value - is universal. Whether a business produces physical goods, manages services, or delivers digital products, the Lean approach helps organisations become more agile, resilient, and customer-focused.

In closing, adopting the five key principles of lean manufacturing is not simply about adopting new tools or processes. It requires a mindset shift: a commitment to continuous improvement, respect for people, and a willingness to challenge the status quo. The journey may require discipline and patience, but the long-term benefits - improved performance, customer satisfaction, and profitability - make it a worthwhile endeavour for any organisation.