In many instances, electronic components have to operate in harsh environmental conditions. For companies producing them, it's a big challenge to protect electronics against harmful conditions effectively. The variety of electronic and photonic components is enormous and, therefore, a given factor that has an adverse impact on one element, can be completely neutral to another. We have to struggle with lots of various harsh environments: humidity, dust, water, chemical substances, high/low temperature, and more. What can be done in order to protect electronics against these factors?

Today, electronic devices have to work in various environments and conditions. And let’s cut straight to the chase–the vast majority of them has an adverse impact on electronics. They can be found in environments with a high intensity of each of the aforementioned factors. The list is quite long and also comprises mechanical disturbances (vibrations and shocks), electrical disturbances, or ionizing radiation (chiefly in the space industry).

The material's resistance to harmful conditions results from the appropriate construction, selection of components, and proper protection.

The influence of harsh environmental conditions on electronics

The greatest enemy of electronics is moisture. It is the primary factor causing corrosion. The water in our world is full of minerals and other substances. For example, typical tap water may contain calcium, magnesium, sodium, potassium, chlorides, nitrates, iron, copper, and more. Moisture in the air also contains similar substances, as well as solid particles from air pollutants or industrial pollutants.

These substances produce positively and negatively charged ions. These ions conduct water (electrolyte solution), causing an electrical short circuit in the electronics. Further evaporation will leave these particles, salts, and minerals behind. Many of these substances act as corrosives, damaging circuits, and electronic components. Often, even the best-designed and constructed system loses with humidity.

Another factor that frequently has a negative impact on electronics is temperature. Fluctuations in ambient temperature during an electrical device's operation can have a huge impact on its stability. Moreover, exposure to high temperatures may adversely affect the speed of the device. Components that are constantly exposed to high temperatures are particularly vulnerable to damage. Devices with standard construction, without adequate protection, can be damaged very quickly and exposed to such extreme conditions.

This begs the question – what can you do in order to protect electronics against these conditions? Thankfully, we are not in a no-win situation. Currently, there are two different, most commonly used ways of protecting electronics available:

- Conformal coating

- Potting

Let’s take a closer look at both of these techniques.

What is a conformal coating?

The application of protective coatings is used because the electrical circuits on the board (PCB) are more and more delicate structures. The varnish also reduces the risk of growth of the so-called whiskers. Thus, it eliminates the risk of dendrites, corrosion, and short circuits, which, in turn, enables the longer operation time of the device. This is extremely important from the point of view of the quality of products offered by electronics manufacturers.

In order for the above-mentioned advantages to be met, varnishes must meet appropriate conditions such as flexibility, and resistance to temperature changes and vibrations. It is very important that they have resistance to moisture or puncture, have good insulating properties, and have good chemical resistance and permeability to the substrate.

There are several ways to perform conformal coating. Unfortunately each method has some pros and cons. The choice of the wrong application method or the incorrect application of the varnish can significantly affect the efficiency of the coating and the performance of the PCB. So, what to choose?

Application with a brush

As the name suggests, this method is based on applying varnish to the printed circuit with a brush. The advantages of this method of application are, above all, that it can be more economical in small-scale production and that it is easy to select the areas to be coated.

However, we usually do not recommend brushing as it is not always easy to apply an even coat.

This may result in a lack of adequate protection in the case of a coating that is too thin, or cracking in the coating when it is too thick (especially with cyclical temperature changes). It is also worth noticing that it can only coat one side of a printed circuit at a time.

Dip application

This method involves machine immersion of the entire printed circuit in the coating, which allows the coating to penetrate the gaps and spaces under the components that are otherwise difficult to access.

In such a case, the material must have a sufficiently low viscosity to penetrate into the casting pores freely.

Some PCBs may not be coated with this method due to their construction, especially if the components are close together.

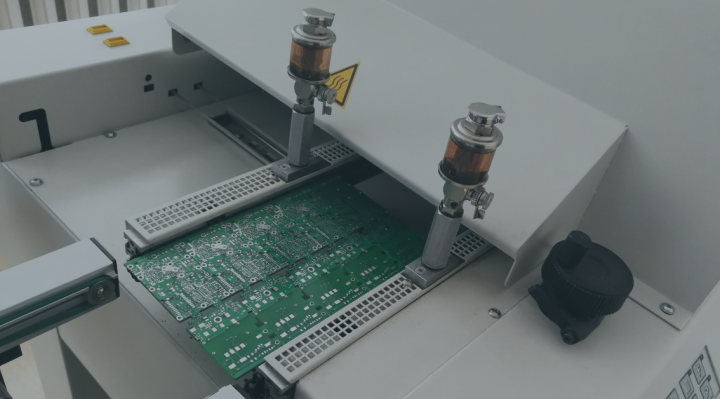

Selective machine application

Selective machine application is a method by which the printed circuit elements to be coated are "selected". Typically, this method utilizes a machine that is programmed to coat only selected areas. Machine application guarantees an even and reproducible coating of the recommended thickness.

Application is usually quicker and is suitable for continuous production of the same parts.

The disadvantage of this method is that it requires a more skilled operator, and penetration into components is not always easy. It can also cause coatings to "thread" or bloom to form on the surface.

Spray application

Spray application, as its name indicates, is a method of spraying lacquer onto a printed circuit. It’s usually done by hand in a spray booth or with an aerosol. Nevertheless, this method can be automated, as in the case of selective application.

It is one of the most economical and convenient ways to apply coatings as it can be done on a workbench if needed.

The disadvantages of this method include the possibility of overlapping layers, resulting in a coating thicker than recommended. When spraying with a machine, it can also be difficult to reach the underside of the components. Finally, the method may also "thread" the coatings or cause efflorescence on the surface, engineering experience in preparation phase is very important, it requires also to predict possible capillary effects.

What about potting?

One of the methods of protecting electronics against the influence of the external environment is potting the entire PCB in the housing. This solution protects the system against the influence of external factors, mechanical damage, and against unauthorized access when an opaque material is used.

Potting can be done manually or with the use of a special machine. The manual method is based on priming, and it involves mixing the ingredients in a container. However, incorrect measurement of individual ingredients may lead to the fact that the resin will not harden. Improper mixing can trap air inside the resin, which will weaken the strength of the construction and deteriorate its electrical insulating and thermal conductivity properties, it may be difficult to spot if resin mixed manually harden completely or we have sort areas inside.

The second manual method is priming with cartridges – where each ingredient is placed in a separate cartridge, and the cartridges are connected to each other. Their volume corresponds to the mixing ratio, so we can be sure that the proportions will be kept. A static mixer ensures that the ingredients are properly mixed without the risk of air entrainment. The use of this method is limited due to the availability of resins in the cartridges.

Flooding, like other methods of securing electronics, is becoming more and more popular. It is an additional operation and cost in production, in return for which you get electronics perfectly protected against external factors and unauthorized access.

Choosing the right protection is difficult and requires analyzing legal, environmental, and production requirements. However, it should be remembered that performing such an analysis at the beginning of the design process may significantly reduce the total cost per one device. Experience shows that companies usually start with the simplest methods: brushing or spraying. This allows you to perform small projects and learn the technology, its limitations, and requirements.

However, with a certain scale of production, the costs of ventilation, personal protection of workers, material losses, and production time are so high that the only reasonable solution is a specialized machine for selective coating set up in the production line.