Each and every company in the market is vulnerable to a variety of hazards. Within the context of EMS, the greatest threats to supply chains include increases in raw material prices, fluctuating supply and demand, and natural hazards. From the perspective of supply chain management, it is extremely important for an EMS company to react promptly, appropriately and solve the given problem. Below, we present EMS actions which can effectively solve the problems adversely affecting supply chains.

Raw materials price increase as a threat to supply chains

Raw materials price increases constitute a significant threat to supply chains. Dynamic price growth (which could be observed, for example, from the onset of the COVID-19 pandemic) is particularly dangerous. As such, all unannounced and unpredictable price increases are problematic. It is undeniably true that higher resource prices greatly affect the costs of components, and these, in turn, send the costs of the product and the project through the roof. These days, of course, it applies to almost every raw material. It should be borne in mind that the reaction to increased component prices depends on many factors, such as financial reserves. Moreover, material price increases are related to resource allocation.

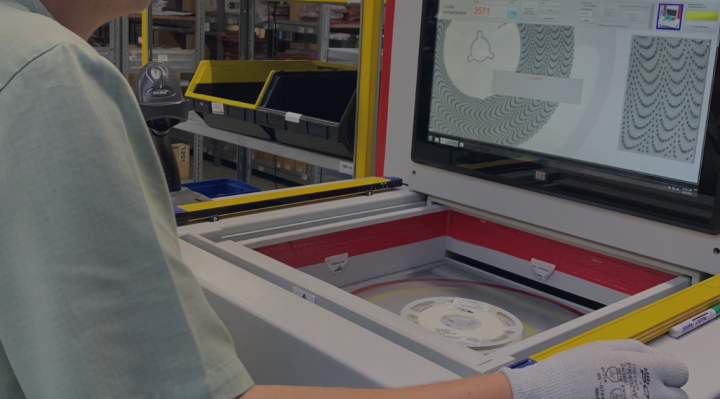

Exactly what can EMS companies do to mitigate the consequences of higher raw material prices within the context of supply chains? First of all, they should be flexible in their responses to all dynamic changes within contemporary material markets. Any rational response to a hazard is impossible without it. By the same token, it is necessary to update the IT system parameters to reflect the new lead time. We should remember that a well-configured system will almost immediately display the new resource order date (in this case, an expedited one). Just as importantly, subcontracted electronics manufacture companies can also propose alternate materials, or allocate specific resources to a given client. Another important factor is flexible allocation.

Demand and supply fluctuations

Demand and supply fluctuations constitute a threat to supply chains, as excessive demand coupled with limited supply can result in noticeable supply disruptions. First and foremost, supply chains can be threatened by a sudden increase in demand for given products. What this means is that certain EMS companies may not be able to manufacture new products in a timely manner. This problem may have numerous causes, the most obvious of which is the inability to deliver large amounts of raw materials on time. For this reason, supply and demand synchronization is vital from the perspective of subcontracted electronics manufacture. Additionally, supply and demand fluctuations are an extraneous factor which the company cannot really control. Nonetheless, subcontracted electronic manufacture companies must bear those fluctuations in mind.

Flexibility (i.e. swift reactions to supply and demand fluctuations) is of paramount importance in EMS activity. Of course, accelerated responsiveness is possible thanks to various planning tools. Just as importantly, EMS companies must conduct market analyses and inform their clients about prospective risks. All this is achievable if they posses expert knowledge pertaining to the production process and effective adaptive measures related to fluctuating demand. This, in turn, translates into increased market competitiveness.

Natural disasters - pandemics, geopolitical upheavals, economic crises and other known natural disasters

Natural disasters are a very diverse category. As such, the constitute a clear and present threat to supply chains, since they greatly disrupt their optimal functions. Pandemics and geopolitical threats can be included in this number. Of course, supply chains can be disrupted by economic hazards and other natural disasters as well. We hardly need to belabour the point that these can adversely affect the production cycle. For instance, the coronavirus pandemic struck a powerful blow to global supply chains. The adverse consequences of COVID-19 were felt worldwide. As a consequence, global markets were beset with raw material shortages and higher prices.

Subcontracted electronics manufacture companies should counteract natural disasters by preparing and using contingency plans. Of paramount importance is the implementation of the ISO22301 continuity management norm. It should be noted that the company needs to implement contingency plans in order to be officially certified. Just as importantly, companies need to quickly react to emerging threats, observe & analyse the situation, and derive logical conclusions.

How should your EMS handle emerging threats?

You must have wondered how your EMS should handle various hazards. As mentioned before, implementing the ISO 22301 norm is essential here, as it focuses on operational continuity management. Of course, subcontracted electronics manufacture companies should consider preparing a contingency plan or two in case of any of the abovementioned hazards or any other threat to functional supply chains. Just as importantly, sticking to the contingency plan will allow us to mitigate the adverse consequences of any threat. Moreover, we should remember to ensure the continuity of production by establishing commercial relations with global and local suppliers.

Let’s face reality - any EMS can be confronted with a crisis. Much depends on external factors. We should pay close attention to how any given EMS reacts to those issues, and if they have any contingency plan to fall back on. If we keep the above in mind, the company’s losses will be mitigated. Of course, any given EMS will try to preserve default production levels, but everything depends on the kind of hazard it faces.