Introducing new products that meet customer expectations is a difficult art, requiring the collection of reliable information and the dedication of time and resources of the entire company. The most successful companies in this respect have an implemented and well-organized process they follow. Thanks to this, they are able to introduce repeatable, serial, high-quality products to the market. In this article, we are going to examine if the New Product Introduction process applies to PCB Assembly.

What is New Product Introduction (NPI)?

Simply put, it is a process aimed at developing a scheme for serial production of a given product. During NPI, the prototype is transformed into a carefully finished and fully reproducible end product. The deployment process is iterated until the end result is achieved. New Product Introduction is extremely demanding. Each stage has to be planned and reliably carried out. Only this way, companies can ensure that the achieved result will be worth their work and effort.

NPI - one of the most important processes in PCB Assembly NPI

Companies that deal with PCB Assembly, and are thriving on the market, realize how important it is to implement the NPI process. It allows you to avoid possible changes, numerous corrections or repeating tests at a very early stage of assembly. In other words, NPI guarantees the repeatability of the production process of high-quality products, thus preventing many future errors and minimizing the risk of unexpected costs.

Only PCB Assembly companies (EMS) that use NPI are able to consistently provide customers with high-quality products.

Key Benefits of New Product Introduction

In the case of most manufacturing companies, but also in the case of the PCB Assembly suppliers, New Product Introduction primarily ensures that the manufactured products meet the standards required by customers and the market itself. Thanks to this process, electronics companies can be sure that they deliver high-quality, repeatable products to the market. All of that at the right time and with full control over costs. The process of introducing a new product of course also has other advantages:

Allows to avoid problems with the quality

NPI allows you to detect potential errors at the design stage. Thanks to this, before starting serial production, it is possible to detect any errors regarding components or design.

Requires testing

When introducing a new product, a number of various tests are performed, thanks to which PCB Assembly supplier can be sure that its product meets all customer requirements. In particular, it is important to carry out an SPI/X-Ray inspection, RLCD examination, and verification of documentation.

Saves time

The consequence of implementing NPI is the development of a repeatable production process based on best practices. This allows you to eliminate non-value steps and focus efforts on key aspects of the assembly. All that gives the PCB Assembly supplier full control over the total time of introducing a new product as well as over each of its phases.

To take full advantage of NPI possibilities in the field of PCB Assembly, it is worth using the Design For Manufacture service in advance. This will allow you to determine the optimal production methods in terms of the economy of the process and its scale, taking Lean Management into account.

The NPI Process

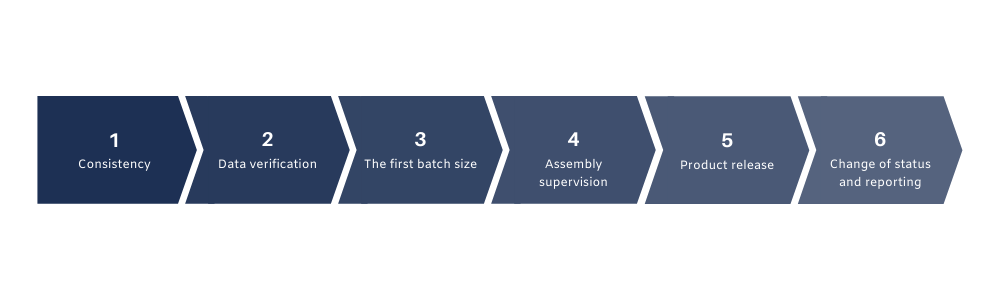

As mentioned above, NPI is a very complex procedure, based on which several separate models and schemes have been defined. However, there are some permanent elements that the PCB assembly supplier should take care of:

1. Consistency: Engineers assign an individual NPI number to the product, which will be marked in all reports or created documents. You should automate this stage with a special program to minimize the risk of potential errors that can be caused by manual data completion.

2. Data verification: NPI engineers should first verify that they have all the necessary data and equipment to make the first batch. Their later absence may result in an unnecessary stoppage of the team's operation.

3. The first batch size: At this stage, it has to be determined how many products should be made during the first production. Usually, it's a huge mistake to produce the entire batch in the first round. Most often, it is ten panels.

4. Assembly supervision: An NPI engineer should constantly supervise assembly. He should carefully document all conclusions and observations.

5. Product release: If the NPI engineer overseeing the process is not satisfied with it, they should clearly indicate this to the client and look for a solution.

6. Change of status and reporting: The entire process ends with a change in future products' status and the creation of a report explaining the product building process. It should also contain a description of all problems that arose during the assembly phase.

At each stage of the NPI process, specialized analytical tools are used to eliminate any errors or obstacles that may arise during production, PCB assembly, or final assembly. This process flow can guarantee that the same products are produced consistently.

NPI in PCB Assembly

Once the intended use of a new product is established, work on modifications and improvements begins. NPI engineers perform the necessary tests and inspections to verify the correctness of the physical placement of individual components.

In the PCB assembly field, it is also essential to continually monitor the assembly process and document the conclusions. A thorough observation of each assembly stage enables continuous improvement of each subsequent batch's quality and efficiency.

The implementation of the new product launch procedure requires a number of activities. Some of them are easy to predict; others may appear unexpectedly during work. However, it is currently difficult to imagine a reliable electronics manufacturer that would not have implemented the NPI process. In short, this process guarantees the correct PCB assembly.