PCB assembly - the basis of medical device success

Due to growing demands regarding performance as well as arising from the applicable standards, OEM manufacturers are facing a difficult task of ensuring the safety and appropriate quality of their products. In the process of medical device production, the printed circuit board (PCB) assembly is especially important as it is associated with the necessity to meet the requirements of ISO 13485 and MDR, as well as a set of other issues, to ensure high quality and safety of the products.

The most important issues related to medical device PCB assembly

Medical device safety

Medical devices are used in diagnosing and monitoring a patient’s health status as well as for treatment. Some come in contact with the body and must be resistant to vibrations, moisture and temperature changes. Others are used in laboratory and clinical procedures. However, regardless of their intended use, during design and assembly of PCBs in medical devices, the safety and reliability of the final product are the most important.

Therefore, when contracting the production of medical devices, it is worth entering into cooperation with an electronic manufacturing services (EMS) provider that does not only help eliminate design for production (DfM) errors and implement corrections to increase device safety, but also properly designs the new product implementation (NPI) process, i.e., its proper prototyping, testing and industrialisation, as well as plans the activities related to quality assurance.

Component quality

High quality of components is of key importance for long-term reliability of medical devices. Thus, the components must be characterised with proper performance and dependability, which means that they should come from trusted suppliers.

Appropriate handling of materials, preliminary inspection, component storage according to their manufacturer’s instructions and industry standards, proper management of EPA zones, and moisture sensitivity level (MSL) control are as important. They help minimise the risk of defects throughout the entire life cycle of a device.

Obsolete technologies

It is also worth checking if the elements included in the design are not technologically outdated. If such components are used, the EMS provider may recommend replacement elements, which does not only let you avoid problems associated with design readjustment to the requirements of the regulatory bodies, but can also improve the functionality of the final product.

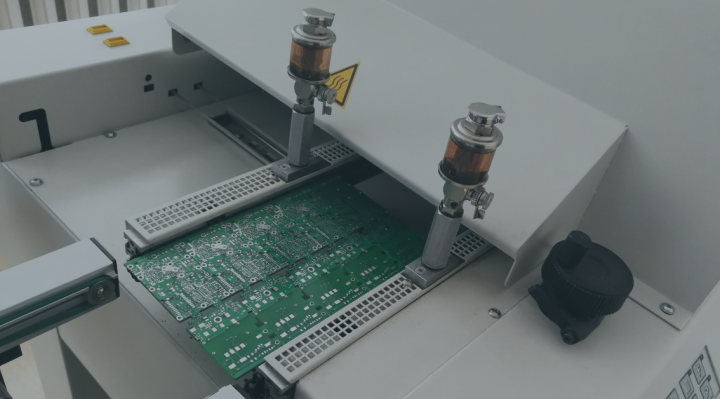

PCBA assembly method

The assembly method, that is SMT (Surface Mount Technology) or THT (Through-Hole Technology), is also crucial for the design. The EMS provider can advise you which of these methods is better in the case of a particular design, as well as recommend possible changes and alternative solutions.

Miniaturisation

For many years, there has been a trend in the industry towards miniaturisation with regard to PCBA assembly in medical devices. With technological progress, medical devices are becoming smaller and smaller, which is associated with the need to precise and advanced PCBA assembly that requires an EMS provider to be highly experienced in this area.

Testing

When choosing your EMS partner, you should make sure that the service provider has well-organised production processes and offers the possibility of product testing that enables monitoring of the quality and functionality of the applied materials and their suitability for the design. Another important aspect is the performance - at the design stage - of appropriate reliability tests that help determine product behaviour in the course of time, as well as product integrity.

ISO 13485 Certificate

Another important aspect is that the EMS provider holds the ISO 13485 Certificate. ISO 13485 is an international standard for quality management, specific for medical device industry. It is an acknowledged standard that specifies requirements for a quality management system in the scope of design, production and provision of medical devices. Holding the certificate confirms that an EMS provider knows and observes the applicable standards regarding medical device assembly, meets high quality standards and constantly improves their processes.

ISO 13485 certification contributes to making medical devices safer and more reliable, and covers such areas as risk management, product traceability, production process control, document management and internal audits.

MDR

Another important standard concerning medical devices is the Medical Device Regulation (MDR). MDR is an EU standard aimed at ensuring high level of safety and quality of medical devices authorised to be marketed in the European Union.

The MDR specifies new requirements for manufacturers, importers, and distributors of medical devices. It defines, among others, the obligations associated with medical device conformity assessment, vigilance and adverse event reporting.

In the context of PCBA assembly in medical devices, the MDR advises additional requirements regarding technical documentation, product conformity with standards, conformity assessment and materiovigilance. EMS provider experienced in the area of PCBA assembly in medical devices is familiar with the above requirements, which enables them to offer OEM support in meeting them.

Choosing your EMS partner

PCBA assembly in medical devices requires taking many key issues into consideration, including safety, quality and reliability of components, selection of an appropriate assembly method, miniaturisation, new product implementation processes, quality assurance and testing, as well as the requirements of ISO 13485 and MDR.

Therefore, the choice of an experienced, ISO 13485-certified EMS provider is necessary in order to be able to offer high quality products conformable with the applicable regulations. Especially after the introduction of the MDR constituting another challenge for OEMs, who now have to meet additional requirements regarding safety and quality to be able to market their products in the European Union. This is why, when looking for a partner in medical device manufacturing, it is worth checking whether an EMS provider is experienced in the execution of similar projects by, simply, reviewing their portfolio.