Soldering is a process that has a specific goal - it is a permanent connection of elements made of metal. This is done by pouring metal details (two or more). You can use another metal for this, which has a lower melting point than the other metals involved in the process. Soft soldering is very widely used in electronics. In this way, you can create permanent connections that will conduct electricity.

What is soft soldering of through-hole components?

• warming up the element's foot (it can be, for example, a resistor)

• heating pad on the PCB (i.e. exposed copper track),

• melting the solder to obtain a shiny and concave solder.

You must remember that only when the solder is melted directly on the soldered elements, you can get a correct connection. To determine the correctness of the connection, you must use the PCB solderability test.

PCB solderability testing - why does it matter?

If you want the printed circuit board to meet the requirements of the IPC class, indicating that its operation will be reliable in terms of the intended use of the board - you need to know the appropriate testing methods to ensure that the required quality is achieved. The PCB solderability test is such a tool. It allows you to reduce the risk of circuit failure, while improving their quality. However, to use the full potential of this test - you need to know its different variants and match them to the final product being tested.

Through the PCB solderability test, you can determine the solderability of instrument assembly terminations that are intended to be bonded to another surface. The main purpose of this test is to check that the PCB component used provides the appropriate degree of wetting - all so that you can create a solid solder joint. A bad test result is important information for the entire production process. This clearly indicates that you are dealing with a suboptimal connection. Without properly tailored tests, costly and cumbersome rework of connections may be unavoidable.

Types of solderability tests

There are three basic methods of solderability testing. Each PCB solderability test has several specific features that allow it to be adapted to a specific application.

What are the types of solderability tests?

• Method 1 - the so-called "dip and look" method dedicated to lead and lead-free terminations.

• Method 2 - the so-called surface mount process simulation test.

• Method 3 - the so-called humidification balance.

Method 1 - the so-called "dipping and appearance" method dedicated to lead and lead-free terminations

Method number one can be broken down into a few fixed elements: pre-preparation, application of flux and immersion of the ends in molten solder. How to describe it in a more graphic way? Test leads and terminals are subjected to an accelerated wear/ageing process in this method. This procedure, after the immersion process is completed, allows to determine whether the tested objects meet the requirements set for them in accordance with the standards.

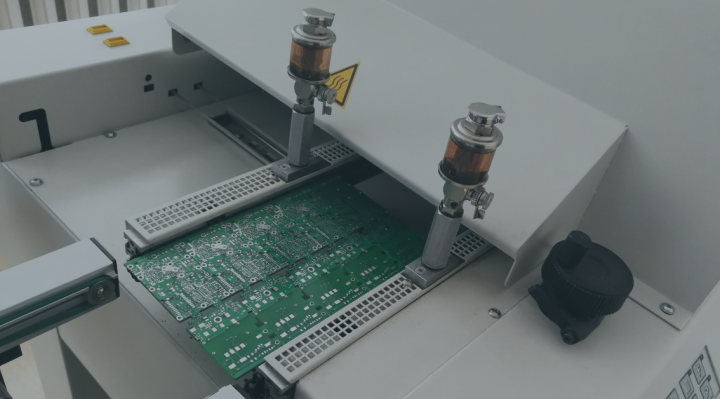

Method 2 - the so-called surface mount process simulation test

With the help of the second method, you will provide yourself with a way to determine the solderability of the terminations in the arrangement of device packages to be connected. You can make this connection with Pb-free solder or lead solder (Pb-). In practice, you have to place a specially formulated solder paste on the ceramic plate through which the test object is passed. Based on this simulation, its quality is tested before it comes to the actual surface mounting using the component. It is important to emphasize that this type of testing can be used for all components of surface mount technology (SMT). It is a very versatile and widely used method.

Method 3 - the so-called humidification balance

Wetting balance, i.e. solder bath, is method 3. During this procedure, the test piece is immersed in a solder bath. In order to obtain the most accurate results possible with this method, a non-contact sensor is used before the measurement. During the test, the wetting force is plotted starting with a negative value. The quality of solderability in this method is assessed by measuring how much time it takes for the object to be wetted.

Regardless of the final choice of the type from the above-mentioned options - knowing about the differences and similarities between them will definitely help you match the appropriate PCB solderability test to your needs and the type of material you work with.

Types of solderability testing with your contract electronics manufacturing service provider

What methods of soldering inspection of components do we offer?

• X-ray,

• visual assessment,

• meniscograph.

What PCB soldering inspection methods do we offer?

• visual assessment,

• X ray.

Each of the above-mentioned inspection methods is distinguished by its own characteristic method of testing. With component soldering inspection methods and “X-RAY” PCBa, you need to use X-rays to perform precise inspections without compromising the components being inspected. Visual assessment (immersion and appearance) is primarily used for lead and lead-free terminations. It can be performed by both a human and an AOI machine - also in a 3D variant. If you choose a meniscograph, you need to know that it is a device that allows you to assess the solderability of the tested materials based on the registration of the Fr force acting on the inspected substrate.