The REACH regulation, enacted by the European Union in 2007, regulates the production, import, sale and use of chemical substances. The regulation contains a wide range of information regarding the registration, evaluation and application of restrictions on chemicals. The implementation of the regulations was intended to protect people and the environment from potentially harmful substances. From then on, companies have to prove that the substances they produce or import do not endanger health and life.

How does the REACH directive work?

One of the companies’ responsibilities is to collect data on the properties, uses, as well as potential risks of the application of a particular substance, and then send it to the European Chemicals Agency (ECHA) in the form of a registration. The agency can check at any time whether the information provided complies with formal requirements. It is worth noting here that ECHA can request new information on the risks at any time, as well as demand updates to the chemical safety report. The REACH regulation applies to basically all chemicals - not only those used in industrial processes but also in everyday life. Consequently, it can affect companies that are not directly involved in the production of chemicals. Entrepreneurs must therefore be constantly concerned with REACH compliance issues.

Is compliance with REACH mandatory?

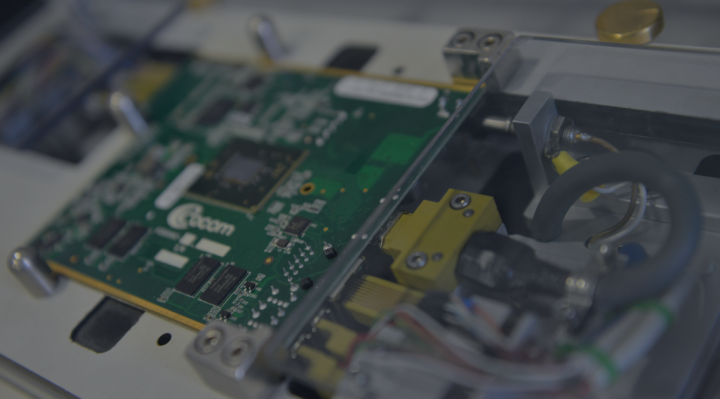

U.S. companies exporting goods to the European Union have to comply with registration and authorization requirements to meet REACH guidelines. Failure to comply with REACH can result in the exclusion of your company from European markets. Fortunately, electronics manufacturers already know how to determine REACH compliance. Any reputable company involved in PCB design and assembly will provide reliable information on risks and alternatives.

Some printed circuit board manufacturers provide third-party tools to help determine whether electronic components are REACH-compliant or choose to assemble software in-house so that they have the ability to constantly monitor their manufacturing processes. This allows companies to verify that everything they produce for the EU market complies with current regulations. It is worth noting here that the chemical management system should not be equated with the EMS, that is, the environmental management system, but can be a part of it.

Differences between REACH and RoHS compliance

RoHS stands for Restriction of Hazardous Substances. This directive originated in the European Union and restricts the use of certain hazardous materials found in electrical and electronic products. Compliance with this directive means that restricted substances cannot be used in the final product. In contrast, REACH controls all chemicals that can be used in the manufacturing process to produce all system components.

Product Owner vs. EMS – who is responsible for component compliance with REACH?

The main benefits of OEMs complying with regulations relate to both worker safety issues and greater product reliability. In an era of increased environmental awareness, manufacturers and suppliers are obliged to ensure the efficient transfer of information on chemicals and their monitoring.

However, it should be noted here that companies providing electronics manufacturing services, who are assembling Customer products using Customer-specified components, and on original equipment manufacturers' (OEMs) behalf, are not responsible for product or component compliance with REACH.

Responsibility for aspects of compliance with certification rests with the customer as the customer is the one who indicates the specific components that EMS is about to purchase and mount. Contract electronics manufacturer purchases components according to the BOM, therefore the contractor does not influence whether the product assembled for the client meets the REACH requirements.

Of course, clients have the possibility of extending the scope of cooperation. At the request of the client, EMS may collect declarations of compliance from suppliers/manufacturers - as an additional service.