Business cooperation does not only consist of signed contracts, agreements, exchange of orders, the flow of goods, services, and invoices. It is also a special kind of bond that is created by the mutual interactions between companies in the market. Starting from the first contacts, the best companies, going through contracts, result in a long-term cooperation based on mutual trust and loyalty towards the contractor.

How can I improve the relationship between "me" and "my" contracted electronics manufacturer?

1. Determine the scope of the contractor's activities and decision-making

Business relationships are often vague, usually making cooperation arrangements ambiguous when it comes to both parties' scope of activities and powers. Suppose this is also the case in your company. In that case, you should do something about it as a matter of priority – always trying to approach cooperation with others individually and in a specific way.

A good partnership is one in which both parties are clear about their obligations. Contract provisions should clearly indicate a number of elements of subsequent collaboration, such as:

- The EMS’ responsibilities – the more detailed, the better. It should regulate the issues that the contract electronics manufacturer must consult with you each time as well as those that they are expected to resolve on their own;

- The production schedule – information about when the PCB assembly will be launched (it is crucial that you provide complete documentation, determine preferred sources of components supply, the scope of tests and inspections, etc.) – the more elements will be discussed before running the production line, the faster you will receive the product) or obtain an estimation of the contractor's production capacity – thanks to this, you will ensure smooth and continuous delivery of the ordered electronics, and in case of a temporary increase of demand for a particular assembly, the contract electronics manufacturer may be more flexible and change their production priorities in order to deliver the required products.

2. Remember to keep in touch with your partner

Companies have started to notice how important internal communication is. Efficient flow of information within teams or between individual units. This is ensured both thanks to direct conversations, e-mail correspondence, and company newsletters, but also by organizing regular meetings.

What improves the quality and efficiency of work so much within one's own organization should also be translated into contacts with contractors who closely cooperate with the company – they are "employees" of the company as well, with their own organization and structure. As an important link in your production process, who you entrust with activity as responsible as the assembly of PCB, a contract electronics manufacturer should be in constant two-way contact with you, which, apart from simply picking up orders, touches upon a broader spectrum of issues.

This turns your contracted electronics supplier into an (almost) equal business partner of yours, with room for more engagement beyond passively following orders – make sure you include them in the discussion and share your short-term as well as long-term company goals with them.

3. Don't be afraid to talk openly about problems

It is with your EMS that you should be able to clarify any doubts and concerns on an ongoing basis, asking them questions at the appropriate organizational levels, and finally set up regular meetings (live or in the form of a teleconference) where you can discuss goals, progress, organizational issues (the PCB assembly itself as well as any changes to it) face to face, other feedback regarding a direct collaboration that is crucial from your point of view.

During these conversations, talk openly about everything – honesty is an important issue. The reason you choose to work with a professional contract electronics supplier is to ensure that production runs smoothly and quality items are delivered. The contract electronics manufacturer, in this case, will be an open discussion partner and transparent with regards to their actions in order to face up to the tasks assigned to them in accordance with applicable laws and procedures.

4. Trust your contractor

A positive economic calculation is the most common incentive to outsource PCB assembly. Apart from this aspect, it is also a peculiar proof of trust for the contract electronics manufacturer. Therefore, before choosing an EMS supplier for your company, it is worth getting to know the entities operating on the markets, checking the websites of potential contractors, for information on how long the company has been on the market, the issue of compliance with production standards, or what certificates it holds. If there is such a possibility, it is worth getting acquainted with opinions about the manufacturer (among others, thanks to recommendations). If, after such a "preliminary analysis" of the contractor, you tentatively decide to establish cooperation with them – visit their plant, conduct a quality audit and see whether, as an organization, they operate professionally and have implemented appropriate management systems.

A contract electronics manufacturer who is serious about their responsibilities will allow you to control the production of commissioned items, in addition to having an open attitude, as part of building a good relationship with you. This will allow you to avoid potential misunderstandings.

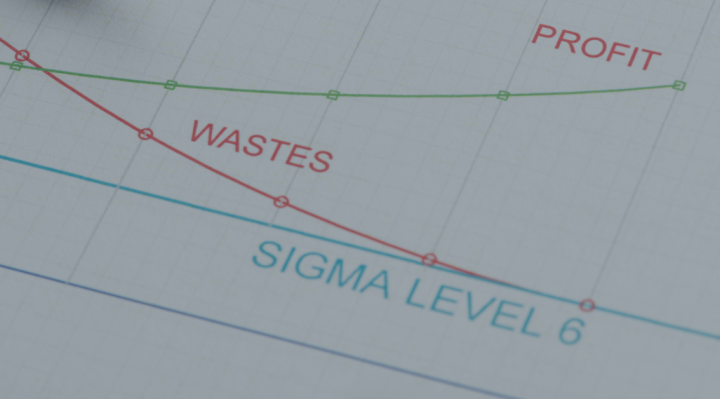

Advantages of mutual trust

With the right atmosphere and terms of cooperation, a contract electronics manufacturer can become one of the vital pillars for running your business. Instead of committing your efforts and resources to tightly controlling the EMS, you can focus on increasing your competitiveness in the market. Collaboration becomes more effective, and in an atmosphere of partnership, it is easier to make changes that may be required in the current PCB assembly scope or to respond more quickly to market demands.