Business management is not simply the matter of the seamless and efficient operation of the entire corporate body on a daily basis. It is also the ability to analyze and plan solutions that will allow an uninterrupted operation and the execution of the EMS's obligations in case of the occurrence of unforeseen situations, often ones being beyond the organization's control, such as a natural disaster, or those occurring in the economic area, and (more recently) in the scope of public health.

An organization prepared for the occurrence of a possible crisis reacts quicker and more efficiently at the moment of its event and can restore its activity to the original condition in a shorter period than organizations unprepared for a given scenario. The scope and pace of actions taken by a company translates into the financial situation and the overall perception of the company by its counterparties and clients alike.

This type of crisis management resourcefulness "test" applies to virtually every business, and it is no different in the EMS industry, where a good contractual electronics manufacturer takes care of their business continuity management.

Business Continuity Management (BCM)

It is a set of actions an organization undertakes to ensure that its critical business functions are available to their clients, suppliers, and employees in the event of an emergency or other disruption of normal operations.

BCM is not only a process carried out during a disruption of business. It also refers to the activities performed every day in order to mitigate the risk of an emergency and maintain readiness to respond immediately should such a circumstance arise.

Works on securing the company against the consequences of a crisis situation may be developed independently, according to the independently created and adopted company policy, or be the result of already existing management standards. One of the standards that introduce the good practice in the scope of business continuity management is ISO 22301 Security and resilience – Business continuity management systems.

ISO 22301 - Continuity Management System

ISO 22301 is an international standard for Business Continuity Management systems. It determines detailed requirements regarding the implementation of an effective continuity management system. Business continuity management aligned with ISO 22301 is based on a thorough analysis and takes into consideration the organization as a whole. It includes resuming the company's works after a breakdown as well as business continuity plans that focus on recovering specific operations, functions, services, etc.

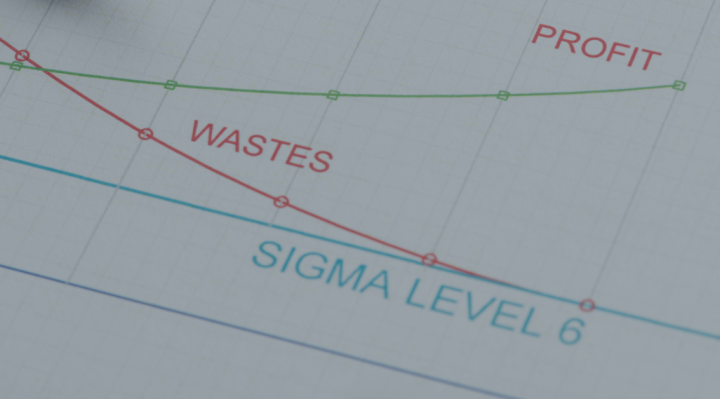

The benefits of applying BCM aligned with the ISO 22301 standard include obtaining new business contracts, protecting revenue and profits, preestablishing a good brand reputation, as well as quicker recovery from a damaging incident, plus compliance with the applicable regulatory requirements.

How can a contractual EMS provider ensure business continuity management?

Complete organization analysis

This is the most demanding and time-consuming stage. Business continuity management should be based on in-depth, broad-context analysis to make sure that the plans developed are as tailored to the specifics of the business as possible. Therefore, as part of this element, information is collected regarding the organization itself as well as its processes that apply Risk Analysis (RA) and Business Impact Analysis (BIA). As a result, the organization's processes critical for further planning are obtained. The parameters of the restoration of these key business processes are extracted. It is verified whether their implementation can be achieved with satisfactory results in the event of an occurrence of a crisis situation.

A good contract electronics manufacturer periodically tests the once established plan and verifies its validity as well as its effectiveness. This includes, among others:

- Tests of business continuity plans: It is a cyclical check of the effectiveness of the emergency plan. In addition to verifying the effectiveness of the adopted operation strategy, it is an effective method of training employees and building their awareness on all levels of the organization.

- Updates: The organization, as well as its environment, is subject to constant transformations. Therefore, regularly checking and adapting to the varying internal and external conditions enables to maintain an effective operations plan in case of a crisis situation.

- An audit: It allows you to determine whether the adopted plan meets the requirements in accordance with the business continuity management policy adopted by the organization, the legal regulations, and standards, as well as the regulators’ recommendations.

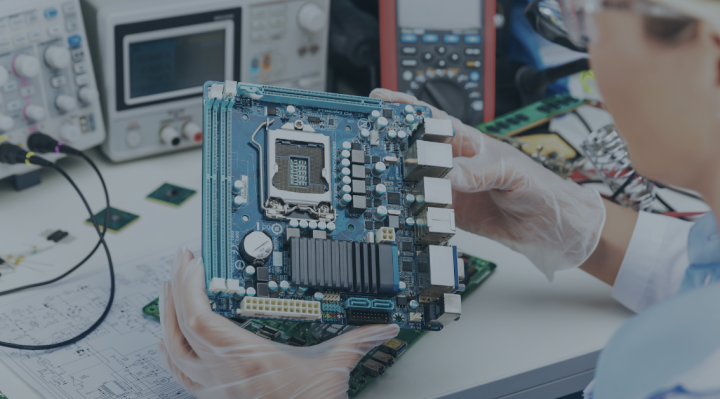

Continuous investment in technology

A contract electronics manufacturer is aware of the fact that one of the most critical points, also in day-to-day operations, is the technology they use. Both in terms of the facilities the company already possesses (the SMT assembly machines should be subject to regular, periodic maintenance), as well as in the scope of upgrading the devices, i.e., replacing them with newer models when they are no longer fully functional or meet the legal standards.

This allows you to avoid interruptions in production continuity and also reduces costs. If a machine breaks down, repairing it is much more time-consuming than periodic maintenance. You should also bear in mind that when the machine is idle, products are not assembled, which ultimately results in a delay (i.e., losses also on the part of the Ordering Party).

Deliberate supply chain management

This element was tested extremely well by the COVID-19 pandemic, showing how the availability of raw materials, intermediate products, and finished products on global markets affects the manufacturing capability of local markets.

Well-managed material planning should be flexible to quickly respond to changes in the market, such as changes in material prices, delivery delays, alternative suppliers of particular components, etc. Good contract electronics suppliers use ERP software. They enter advanced planning parameters, which, processed with appropriate algorithms, allow not only to keep an ongoing control but also to react early enough to operate more efficiently in this area.