Thriving in one's own company is not just about satisfyingly observing growth in monthly, quarterly and annual statements. It is also about planning strategy, growth, facing all sorts of challenges – including insufficient in-house forces to meet the growing market demand for in-house manufacturing.

One solution to this problem for manufacturers in the electronics industry, (so-called Original Equipment Manufacturers (OEM)), is to decide to outsource some or all of their manufacturing by establishing contacts and further cooperation with electronics manufacturing services (EMS) provider.

However, before entering into a business relationship with an electronics manufacturing services provider, there are a number of aspects that are worth taking care of initially to ensure that you can have a productive conversation with potential contractors to whom your organisation would like to outsource electronics assembly.

Preparing for discussions with an electronics manufacturing services provider

Before any requests for quotation are prepared and sent out to EMS, it is important to determine exactly what our company will gain from the outsourcing partnership. What expectations our organisation has in the short, medium and long term, which are likely to be met by contract manufacturing.

Preparing an RFQ – the key to fruitful discussions

Defining expectations at an organisational level should go hand in hand with a clear and as detailed as possible definition of the needs posed by our contract manufacturing. It is worth having a quantitative annual/monthly forecast of the number of products you would like to manufacture and sell, in order to more or less realistically indicate the demand that is a genuine response from the market. Also, defining what services and scope of work the outsourced electronics assembly is to include allows the request for quotation stage (https://asselems.com/en/5-elements-to-include-in-your-rfq-to-an-electronics-manufacturing-provider) to run smoothly. In the RFQ draft, it is worth including such information as:

- the scope of work – limiting yourself to contracting only the assembly of components or having the electronics manufacturing services provider perform a larger scope of work (e.g. assembly of a housing or assembly of an entire product),

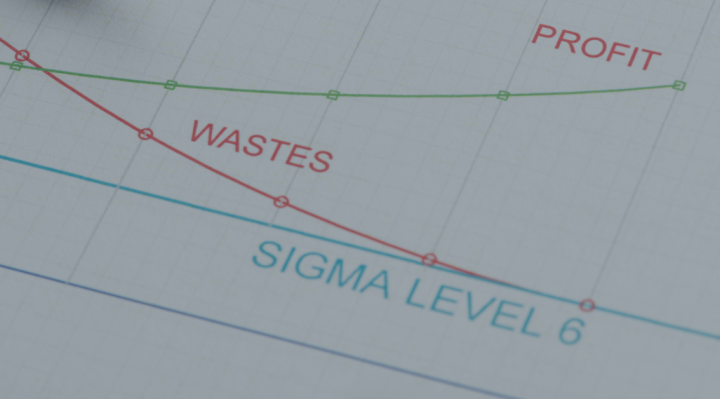

- quality requirements – IPC class, expected material inspection standards,

- testing and inspection – defining the level of quality control and test plan for the product at different stages of manufacturing,

- use of technology to protect the product from adverse environmental conditions (conformal coating or potting)

- product packaging – supplier's standard (if proposed) or custom/own packaging, and informing whether products will be delivered to end customers

Proper EMS search

Only once the relevant assumptions have been pre-defined can the search for potential ESMs begin. Select a few contract electronics manufacturers with whom you think you will have the best business match – in terms of size, whether they match the OEM's strategy, whether they have the desired competences – and only after this initial verification should you move on to establishing direct contact.

In addition to the request for quotation document, it is also a good idea to prepare specific questions before starting the actual discussions. This is another screening to ensure that the electronics manufacturing services provider meets all requirements and to verify its level of compatibility with our business. The ESM should also suit us in terms of scale, so that our project defines a sensible level of turnover for the supplier, so that the scales and the risks are balanced.

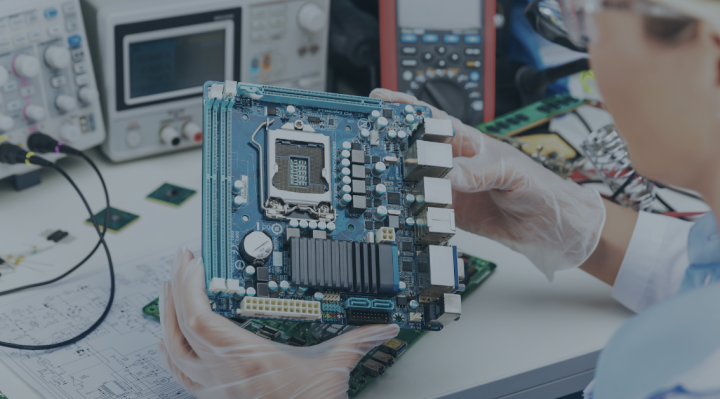

When the discussions are successful, it is also a good step to visit the EMS plant to see how contract manufacturing is carried out in the plant, how it is organised, to get to know the people you will be working with directly – not only the main contact person, but also the whole team responsible for electronics assembly, the company's organisation in terms of supply chain management, the Management Board. In addition, an audit can be considered.

The decision to start outsourcing or to change suppliers is one of the most important ones to ensure that electronics assembly maintains its fluidity and quality. Choosing the right supplier is, despite appearances, a difficult decision, so you need to be sure you have received comprehensive answers to all the important questions. This guarantees that the EMS meets your requirements with the right competence and many years of experience. It is also guaranteed by a visit to the chosen electronics manufacturing services provider's premises to see what contract manufacturing and organisation looks like on a day-to-day basis. All of this makes it possible to successfully select a contract electronics manufacturer in accordance with your needs, culture and work organisation, ensuring a harmonious and long-term cooperation.