Playing a double game is quite risky, whether in business or in other areas of life. Therefore, making a decision to use dual sourcing should be preceded by thorough analyses of your organization and its needs in terms of electronics manufacturing services, which also applies to other branches. In some cases, not limiting yourself to a single supplier – single sourcing can bring an organization a strategic advantage, but before implementing this solution you should be aware of the costs as well as the overall needs of the company.

Dual sourcing

Dual sourcing is a supply chain management practice of using two suppliers for a given component, raw material, product or service. The term is sometimes used outside of its strict definition, as a synonym for multi sourcing, which can involve more than two suppliers.

Advantages of dual sourcing

Companies, including those providing electronics manufacturing services, for which the main business is assembly of electronics, are turning to dual sourcing to reduce the risk of relying on a single supplier (so-called single sourcing), which is an important supply chain risk management strategy. Reducing the likelihood of the supply chain being disrupted by various risks (including adverse weather conditions, material shortages, recalled products, natural disasters and political unrest), are prompting companies to consider dual sourcing options. Having suppliers in different geographic locations also means access to local markets, which, in addition to minimizing risk, increases the pool of markets where we are present.

In addition to eliminating risk, it can also help in business growth, as having more than one supplier allows you to keep up with growing customer demand for electronics manufacturing services, if your company provides comprehensive services of supplying components and finished products. A wider choice of suppliers also means higher competitiveness – you can choose a better supplier to match your customers’ expectations, a supplier whom, in the long run, will be able to complete a greater number of orders for your company.

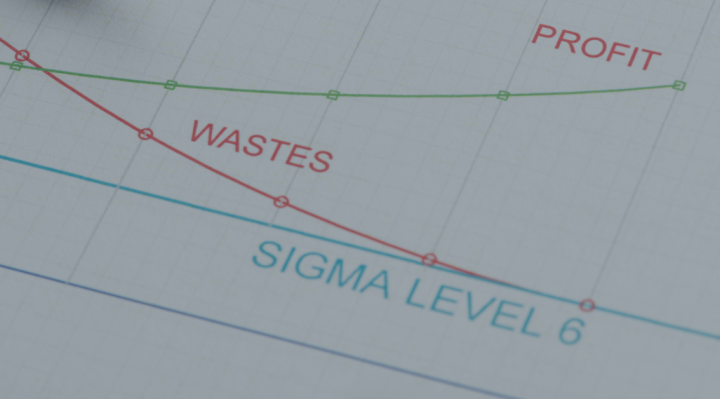

Awareness of non-exclusivity among suppliers also means more options which increases competitiveness. Dual sourcing means working with several suppliers, so there is a chance of greater flexibility, for example in terms of costs, materials and components on which electronics manufacturing services and their final price are based. Suppliers themselves will offer competitive prices to encourage you to start cooperating with them and save money.

Dual sourcing is also a way to prevent supply monopolies. Competition – even between partners of one customer – drives competition. You cannot maintain higher prices in such an arrangement – the cost of services will go down.

Disadvantages of dual sourcing

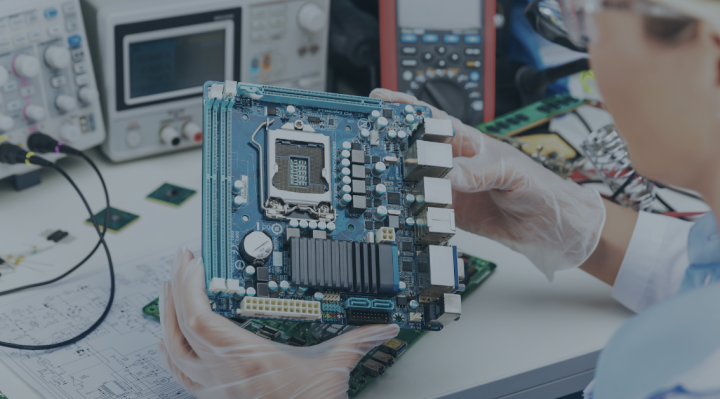

Despite its undeniable advantages, dual sourcing can create new problems for organizations, such as inconsistent quality. The OEM must verify that the products from each supplier do not differ. It must make sure that the products of electronics manufacturing services are identical, no matter which supplier was used.

The complexity of management in this practice is another serious issue. Dual sourcing can challenge production resource planning systems and other organizational management systems as you need to ensure that electronics assembly continues to run smoothly under new conditions. It may require more extensive integration systems to be able to efficiently source from multiple suppliers, generating additional order handling costs.

Additional handling costs can also arise due to different time zones if a company chooses to work with suppliers in different geographic areas.

Dual sourcing is gaining popularity and is being considered by an increasing number of customers. However, it is a solution that should be preceded by an in-depth analysis of the company’s needs and capabilities (e.g., two global locations, large volumes and need for diversification, high production volumes, need for a smaller local partner and a larger one for serial production) in order to use it effectively. Each OEM must decide for itself whether dual sourcing will be a good option, which will bring measurable gain, or whether the cost of handling will outweigh potential advantages of implementing this business cooperation model.