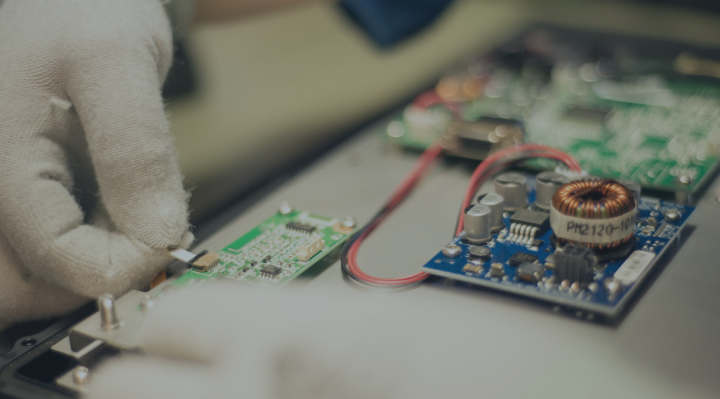

The development of electronics is not only industry, households or entertainment. Electronics, automation and SMART solutions are increasingly used in the medical industry - state-of-the-art medical devices are technological achievements that save and facilitate lives, and disease crises, such as the recent one related to Covid-19, trigger increased demand for specific types of equipment, e.g. ventilators. To meet the needs of the medical market in terms of manufacturing the necessary electronics, you need the right equipment, but you also need knowledge and experience backed by relevant certifications such as ISO 13485.

ISO 13485

Of the many standards in the electronics manufacturing industry on which the production of medical devices is based, one of the most important is ISO 13485 - it is one of the key standards for manufacturers in this sector. This standard defines a wide range of requirements for a quality management system (QMS) for medical devices and equipment.

It specifies requirements for organizations involved in one or more stages of a medical device’s life cycle. It is not the same as ISO 9001 (which also regulates, in general terms, an enterprise’s quality management system) - it extends the QMS framework defined in ISO 9001, while being more applicable to the medical device industry. Device manufacturers and engineering service providers must comply with documentation, management, design and development, traceability, auditing, testing, sterilization and other manufacturing requirements necessary due to the sensitivity of the medical industry.

What does ISO 13485 ensure for a manufacturer?

By using a contractor that is ISO 13485 certified, you can be assured that the electronics manufacturing provider has the ability to deliver medical devices and related services so that they strictly meet the requirements of the regulatory standards that apply to them, as well as being in line with the customer’s expectations.

It is definitely someone who has already had contact with medical devices more than once - ISO certification helps to improve an already existing quality management system in the context of medical electronics manufacturing, which means that EMS provider is ready to cooperate in this area. It has the right experience, facilities and procedures, so it will also help in handling the products, and in the case of possible threats or problems, it will know how to remedy the situation.

Additionally, with an ISO certified contractor, you can be assured that the EMS team is properly qualified and regularly trained in medical device assembly and that the management of the team follows all of the procedures that this standard places on the organization to keep medical devices operational and safe.

Benefits of working with an ISO 13485 certified company

Medical electronics manufacturing is a challenge for both OEM and EMS providers - the medical device industry is subject to strict regulations. For this reason, manufacturers, when entrusting even a partial realization of their product to an external company, need the assurance that their new products will be made in accordance with the requirements imposed on them in order to reach the market safely.

Adapting manufacturing and product quality to slightly different national regulations can be challenging, which is why ISO certification plays such an important role. Recent developments in this standard have helped to align quality requirements for medical devices with those of the US Food and Drug Administration (FDA), which provides a reference point on medical issues for other countries.

Organizations themselves and their customers benefit from implementing the practices described in ISO 13485 - in addition to the regulatory requirements for medical equipment, OEMs can see several other significant benefits when working with an ISO certified contract manufacturer.

Product requirements

- An electronics manufacturing provider using ISO standards ensures that the manufacturing team and all other parties have a thorough understanding of the end customer’s expectations and the required functionality of the end product, such as medical devices.

- Implementing specific procedures on how medical equipment is assembled and training employees on these procedures helps prevent common errors that can occur when medical electronics manufacturing is underway, ultimately ensuring a higher level of safety for the end user.

- Records of the device’s history, which allow the full course of its manufacture to be reconstructed at different stages and their eventual verification.

- Product and process verification procedures are carried out on protocols specific to medical devices, facilitating control over the product and the process itself.

- Legal requirements for documentation and records, force the entire chain to standardise procedures and documentation as they flow through all organisations, allowing for better communication and vigilance over product quality.

Audit and transparency

- A good and well-functioning quality management system should provide an adequate level of transparency, both for auditors and for customers. ISO certified contract manufacturers often share the results of their audits with their customers, showing that they take full responsibility for the medical devices they produce, their quality and safety.

- Applied according to the guidelines, the QMS clearly defines roles and responsibilities for product development stages within the EMS organisation, ensuring that medical electronics manufacturing runs smoothly.

Quality and risk control

- The electronics manufacturing provider fully manages product quality and potential risks, implementing procedures to help avoid them before production begins, as well as catching them in the early stages of production.

- The quality of the product and the whole process is also influenced by trained personnel - EMS provider ensures that the employees involved in the process are continuously and appropriately trained.

Traceability

- Medical devices require special care, which is why they are also subject to strictly planned control of elements at individual stages of production.

- Verification of history, location of PCBs and materials - if a PCB with defective components is found, it is possible to immediately identify all PCBs in the assembly of which a batch with defective components was used, and then replace them. This is extremely important information, because medical equipment is designed directly to save lives. Manufacturing medical devices is also about taking care of the safety of users.

ISO 13485 and COVID-19

The med-tech industry is constantly developing, not only in terms of more advanced tools, but also in the direction of IoT (Internet of things), thanks to which servers located in the network are also used in the broadly understood medicine - medical devices cease to be ‘static’ measuring devices and become a sort of bank of data about the monitored patient.

Medical devices, due to the COVID-19 pandemic, are subject to increased control - including remote management. With the help of a remote connection, doctors can carry out the same efficient care of patients as on the wards - the transmitted data and results provide knowledge about the patient’s condition, how he or she reacts or even whether the patient is comfortable. This situation has shown how important medical equipment is and how the sudden increase in the number of cases requires an immediate response in increasing the supply of such equipment to hospitals - many countries have experienced shortages of equipment.

The increased demand for medical equipment triggered a response from manufacturers. Many companies during the pandemic started obtaining ISO certification to support the medical industry with manufacturing. This is in a way their ‘debut’ in this branch of medical electronics manufacturing, so when deciding to establish cooperation, it is worth paying attention to choose an EMS provider which has had this certificate for a longer period of time, e.g. several years. This will ensure that the system is properly implemented and tested. A contractor who is experienced in the medical electronics manufacturing knows how to avoid common mistakes and can manage risks.