Poland is strengthening its position on the global map of outsourcing and nearshoring services year by year. Investments in modern equipment and technology, as well as the continuous improvement of production processes, make our country an increasingly desirable business partner for many companies looking for a stable and reliable production location.

Companies from the Nordic countries are among those particularly keen to take advantage of Poland's dedicated outsourcing offer - more than 44% of them are already planning to use this type of solution. Especially since, according to the Hays Global Skills Index 2016, the Nordic countries are facing a serious shortage of professionals in many technology-related industries.

Nordic companies in Poland

Poland is currently home to nearly two thousand companies with Scandinavian capital, which have not only located their service centres here, but have invested more than €11 billion and created 170,000 jobs over the past 10 years. Among the best known are Nokia, Electrolux, Velux, Skanska, Skania, Oriflame and - of course - Ikea. The last one manufactures most of its range of products in Poland and employs over 10,000 people, making it the largest Scandinavian employer in our country.

This is not surprising, given that Poland is a huge market with a population of 40 million and offers access to a highly educated workforce.

Outsourcing in Poland

Poland means not only great employees, but also technologically advanced industrial production and high quality services. As well as constant development. Poland's technology industries, including the pharmaceutical industry and the high-tech sector, have been growing very rapidly at a rate of 7-10 per cent per year since 2004. This is why, in January 2021, Poland was at the forefront of industrial production growth.

For this reason, an increasing number of European companies are opening up to our country (as can be seen, for example, in automotive electronics). Especially as the Polish outsourcing market offers precise, reliable and accurate services and production.

One thing must be explained: while outsourcing is an abbreviation for outside-resource-using and involves the delegation of projects and processes to external companies, nearshoring involves the transfer of a company's operations close to where the products are sold.

Experience and technology in electronics manufacturing services (EMS)

Poland ranks 10th in the world and 4th in Europe in terms of attractiveness of countries specialising in offshoring and nearshoring. We should realise that the volume of domestic electronics manufacturing services (ems) is huge and allowed the industry to take the first place in electronics manufacturing within the European Union as early as in 2014. And also to earn around EUR 14 billion. At that time, more than 50% of electronic devices manufactured in the EU were made in Poland, with 80-85% of electronics exported abroad.1

Therefore, Poland can offer not only extensive experience in electronics manufacturing services (ems), but also a specialised workforce. Especially since, as mentioned earlier, companies are constantly investing in state-of-the-art solutions, processes and technologies, such as assembly of components on metal substrates (metal-core laminates for LED lighting) and 3D assembly.

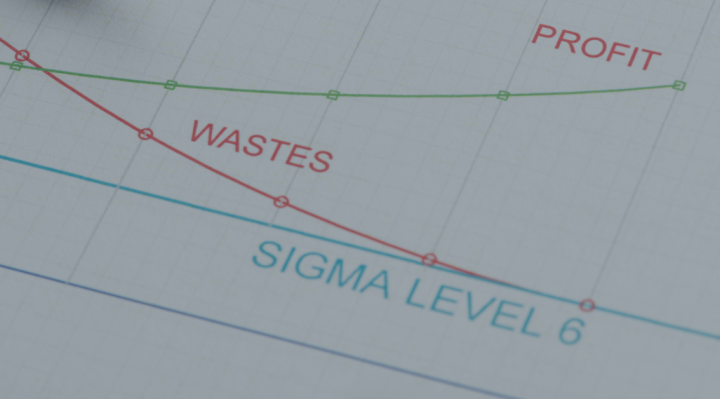

At Assel, we use the latest machines and technologies that allow us to streamline and optimise our production processes (AOI, X-Ray, conformal coating and potting), as well as to control production at every stage thanks to specialised MES software and, thus, eliminate possible mistakes.

Why should the Nordic countries outsource their electronics manufacturing to Poland?

If there is one thing that is very important for OEMs, it is, of course, production costs. And Poland is still able to offer lower prices than Western European companies and costs similar to Asian companies. Especially since companies located in Asia, and especially in China, have recently had to deal with a rapid increase in wages, rising transport costs and burdens that raise overheads.

From the point of view of companies from the Nordic countries (Norway, Sweden, Denmark, Finland), Poland is, moreover, the closest production market, which makes it possible not only to control products on an ongoing basis, but also to reduce delivery times to a minimum.

Additionally, the lack of time difference (as in the case of China) and cultural differences facilitate communication and mutual cooperation. Especially since Poland's economic situation is stable, the quality of production is high and the legal solutions adopted throughout the EU are the same. The latter is particularly important in case of discrepancies between business partners, as similar legal systems facilitate conflict resolution and provide security.

Poland also offers free access to the European market and a well-educated local workforce that speaks English. Especially since Polish technical universities educate more than 15,000 new specialists every year.

Contract electronics manufacturing services (CEM)

Cooperation with companies operating in the Tri-City area provides quick access to business partners and instant delivery of finished products.

Currently, Gdansk has permanent, direct, inexpensive air connections to many cities in Norway, Sweden Finland and Denmark, such as Oslo, Bergen, Alesund, Stavanger and Tromso (Norway), Stockholm and Goteborg (Sweden), Helsinki, Turku (Finland) and finally Copenhagen and Billund (Denmark).

The combination of Scandinavian and Polish production culture yields great results. Poles bring an entrepreneurial spirit, ingenuity and commitment to the cooperation, which are perfectly matched by Scandinavian working patterns, creating lasting business links that benefit all parties.

1Information taken from data provided on the Rzeczpospolita website.