Outsourcing of business services has become the norm in the reality of doing business in the 21st century. This is the manner in which many companies, regardless of their size, are shaping different areas of their organization, such as handling their company's IT services, accounting, or human resources. What about manufacturing outsourcing? Does contract manufacturing of electronics by external entities make sense?

Here are the reasons why SMT assembly by an EMS provider is a good solution.

1. Focusing on the product and selling it

When you outsource your PCB assembly to an EMS provider, you are not directly involved in the PCB manufacturing process. It is the contractor who is responsible for manufacturing, solving problems that may arise (e.g., operational problems related to the availability of components, organization of the supply chain, the manufacturing process, as well as ensuring efficient manufacturing machines or adequately qualified equipment operators) and incurs the necessary financial expenses related to them.

This provides you with something that is never in abundance in business - time that you can use effectively to undertake and intensify other activities. You can allocate your time, energy, as well as financial resources saved to further product development, more effective building a distribution network, and acquiring new clients. All activities undertaken in this context constitute value-added, which positively affects the activity of the entire company.

2. Lower investment translating into positive economic balance

The development of your own business is not only the physical growth of an organization, namely adding new floors to an office building or new production halls. The company's development is also the skillful use of an external, specialized supplier in certain situations. Therefore, whenever it’s possible, the OEM (Original Equipment Manufacturer) can or even should make full use of its EMS provider's knowledge and expertise. Contract manufacturing of electronics is the cheapest and most economically optimal option for the employer. Why?

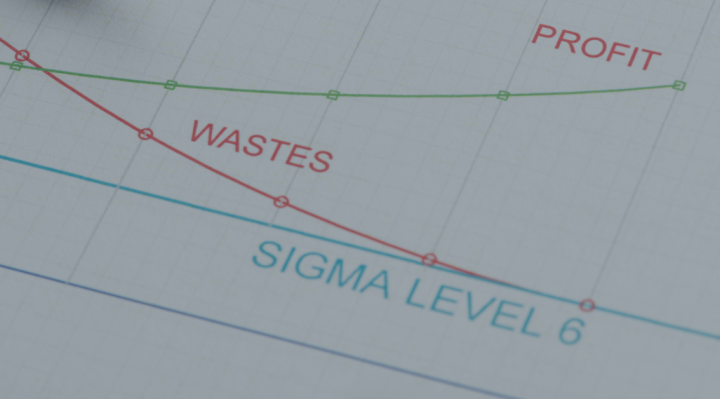

PCB assembly is not only about having the right class of equipment or advanced and modern PCBA technology. It is also about having suitably qualified people who can handle it, and this is what a good EMS provider has. Thus, they are able to provide cyclical manufacturing (according to the client's demand for SMT assembly) and fixed production costs. It is also the developed optimal level of production management, which allows them to cope with such factors as sudden changes in material prices or short product life cycle.

Outsourcing the assembly of printed circuit boards to an external company also means not having to make relatively large investments, often requiring long-term loans, to set up your own fully functional production facilities. There are economies of scale at work here. The fixed costs of production organization (among others, the costs of building maintenance, staff training, machinery park, supply chain organization) are spread over many clients, which makes it altogether a cheaper option for the employer, compared to the costs of organization and maintenance of their own assembly. This significantly affects the final cost of manufacturing the product, lowering it.

3. Experience and high quality of PCB assembly

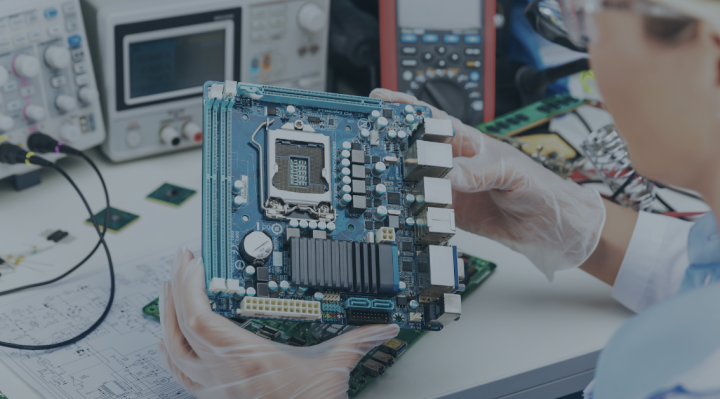

Contract manufacturing of electronics is not just about having the right machinery. Achieving a quality product is a process that should be overseen by experts – people with a wealth of experience who have access to the latest technology and know how to utilize it. Such people have a real impact on the smooth running of the manufacturing process, as they are able to react quickly and solve potential problems, thus being able to control unforeseen situations.

High quality of the services offered is also guaranteed by the EMS provider who holds:

- ISO certificates. Meeting such standards as Quality Management Systems (ISO 9001 or ISO 13485 – for medical devices), gives a potential OEM a guarantee of a very good organization of the manufacturer, which also translates into the production process, its improvement, as well as the path of solving the encountered problems.

- IPC standards – especially classes 2 and 3. These guidelines relate to the acceptability of errors detected in the process of visual quality control for electronic assembly processes. The standard distinguishes 3 classes (the higher the class number, the higher the requirements for the final quality of manufactured systems), characterized by their own specific verification criteria.

4. Supply chain organization and management

Infrastructure, machinery park, and having the right staff to perform PCB assembly successfully is half the battle. Why? Manufacturing organization also means taking care of supplying necessary components, as well as regularity and timeliness of their delivery. It also means assuming full financial risk related to sudden increases in material prices or ensuring the liquidity of supplies at the time of encountering shortages on the market.

Therefore, this is one of the aspects that may prevail in the decision to have contract manufacturing of electronics done by a third-party EMS provider. In such a case, it is the contractor who bears the full burden of procuring all the elements necessary for the execution of the commissioned circuits – from the selection of their supplier, through the establishment of the delivery schedule, to the storage of these elements, as well as being responsible for the management of the material already in their possession. Material management in the process plays an important role, among others: managing it, storing it in appropriate conditions so that it can be used during the execution of the next production batch for the client.

5. Comprehensive service for electronics manufacturing

Maintaining your own production facilities only makes sense when your demand for SMT assembly is constant and sustained at a level high enough to keep your own production moving. Otherwise, the line will generate high fixed costs.

Therefore, if these types of fixed expenses are too much of a financial effort, it is better to use an EMS provider. A contract electronics manufacturer specializing in sub-assembly manufacturing will be able to provide its principals with comprehensive service – from PCBA to final product – with the desired production volume. At the same time, he will have the experience and skills necessary to build a dedicated solution for the client from scratch. Thanks to this, the entirety of work on your order will be carried out within one plant, without the need to engage additional contractors to perform a small part of the necessary work (which would also incur additional costs and logistical problems for the undertaking).

6. Flexibility

Completion time for PCB assembly can be critical to bringing a new product to market or providing the right service for an existing one. In order to meet the expectations of the final recipient as to the availability of the products, it is necessary not only to plan the supply chain and the production itself skillfully but also to have strong planning mechanisms, which allow for precise production planning (in accordance with the demand for components predicted by the client) and appropriately early purchase of the material. A good EMS provider is able to provide this to their OEM. They also have an established business relationship with suppliers and excellent knowledge of market realities, and these aspects can positively influence the purchase price of materials for their customers.

7. Higher assembly capacity

High assembly capacity is not only about keeping your production capabilities up to date with your current demand. It is also about having reserves of capacity to serve the needs of a temporary increase in production, which suddenly appear due to increased demand.

An outsourced EMS provider has more production capacity and resources (including staff) and can therefore plan production in a much more flexible and dynamic way. Increasing it or setting it as a priority in a given period of time for a particular client is, therefore, something realistically achievable at a level satisfactory to the client. This is a gain for the OEM that commissions their sub-assemblies – thanks to that, they do not lose the opportunity to sell more of their own products during increased, unexpected, short-term demand (production peak) for a selected product from his product range.

Contract manufacturing of electronics makes sense. It saves money, which results from the economic calculation (space, equipment, personnel, etc.), and ensures a seamless supply, without having to engage your own forces and time to handle the additional demand, even at the moment of short-term increased demand. It is also the right solution when there is a shortage of experienced SMT assembly specialists who, besides doing repetitive work, cannot solve problems that arise or offer custom solutions that may turn out be necessary.